Search Knowledge Base by Keyword

-

Case Studies

- A Sugary Sweet Lifting Solution for Peeps & Company Retail Store

- Bayside Harley’s Product Showcase and PFlow Bring in the Riders

- Books Arrive in Underground Archive with the Help of a PFlow Conveyor

- Creative Design Highlights Vertical Conveyor at Laminated Glass Plant

- Custom Designed Hydraulic VRCs Help Maximize Space at Tyson Foods

- Custom Designed PFlow F Series Assists with Funeral Services

- Custom PFlow Lift Helps Create 9,600 SF of Storage within Existing Building

- Everything is Bigger In Texas – Including the PFlow M Series VRC!

- For Moving Fragile Cargo, Boeing Called PFlow Industries

- FuelCell Energy Loads Components with the Help of PFlow Material Lifts

- Georgia Pacific Moves Finished Product with the PFlow M Series

- Global Logistics Leader Doubles Productivity with PFlow Lifts

- Gravity Makes the Wine, PFlow Vertical Lift Takes Care of the Rest

- High-Capacity Mezzanine Lift Effortlessly Elevates 15,000 lb Payloads

- Historic Pritzlaff Building Repurposed Into Popular Event Venue with Assist from PFlow Hydraulic VRCs

- Liberated By Upward Mobility

- Manufacturing Plant Replaces 10-ton, 200′ Hoist with PFlow Vertical Lift

- Merged Controls of PFlow Lift and Laundry Cart Washer Regulate the Flow of the Entire System

- Milwaukee Waterfront Deli and PFlow Deliver

- Moving at the Speed of Fashion

- Moving-Floor Assembly Line Streamlines Implement Production

- PFlow and Parking Vault are Solving Major Parking Needs

- PFlow Automated System Provides Continuous 2-Way Pallet Flow

- PFlow Corners the Market for 'Big,' Heavy-Duty Material Lifts

- PFlow Designs Lift for Underground Parking at a Lake Tahoe Home

- PFlow F Series Helps Retailer Utilize Difficult-to-Access Space

- PFlow Galvanizing Provides a Protective Coat for Juice Plant Lift

- PFlow Heliport Lift Helps Offshore Oil Platform

- PFlow Helps Repurpose Restaurant into Government Service Facility

- PFlow Hydraulically Powers the Upward Expansion at Alcom Electronicos Reynosa Facility

- PFlow Lift Integrates Perfectly with 10-Story Power Plant Tower

- PFlow Moving Concourse Helps 'Big Bertha' March Into College Stadium

- PFlow Navigates Uncharted Territory with Vertical Lift at Naval Drydock

- PFlow Pallet Elevator is the Vertical Lift Solution for Nutrilite Warehouse

- PFlow Provides Steady Travel for Lockheed Martin Missile Plant

- PFlow Retrofits 2 Lifts in Single Shaft to Keep Hospital Supplies Moving

- PFlow Screw Lift Provides a Safe and Controlled Movement of Satellites

- PFlow System is an Integral Part of the Paper Production Line

- PFlow VRC Keeps the Pipeline Full for Large Pharmaceutical Distributor

- PFlow VRCs Help Keep the Beer Crisp and Chilled at NFL Stadium

- PFlow VRCs Installed in Concrete Shaft Ways of Seattle Tunnel Project

- PFlow VRCs Provide Vertical Logistics at High Rise Audi Dealership

- Stage Lifts Spirits – and Nascar Vehicle

- Tower Above the Competition with a PFlow Vehicle Display System

- Unique Lift System Enables Installation and Servicing of Telescope Mirrors

- Show all articles ( 30 ) Collapse Articles

-

Preventive Maintenance

- 21 Series Hydraulic Lift - Preventive Maintenance Checklist

- B Series Box Lift - Preventive Maintenance Checklist

- D Series Hydraulic Lift - Preventive Maintenance Checklist

- DB Series Package Handling Lift - Preventive Maintenance Checklist

- F Series 4-Post Mechanical Lift - Preventive Maintenance List

- M and MQ Series Mechanical Lifts - Preventive Maintenance Checklist

-

Service Bulletins

-

Installation Manuals

- 21 Series - Hydraulic VRC - 2-Post Cantilever - Installation Manual

- 21 Series - Hydraulic VRC - 2-Post Straddle - Installation Manual

- B Series - Box Lift - Owner's, Installation, and Maintenance Manual

- D Series - Hydraulic VRC - Installation Manual

- DB Series - Package Handling Lift - Owner's, Installation, and Maintenance Manual

- F Series - Mechanical VRC - 4-Post Installation Manual

- M Series - Mechanical VRC - 2-Post Cantilever - Installation Manual

- M Series - Mechanical VRC- 2-Post Straddle- Installation Manual

-

Owner's Product Manuals

- 21 Series - Hydraulic VRC - Owner's Manual

- B Series - Box Lift - Owner's, Installation, and Maintenance Manual

- D Series - Hydraulic VRC - Owner's Manual

- DB Series - Package Handling Lift - Owner's, Installation, and Maintenance Manual

- F Series - Mechanical VRC - Owner's Manual with Eurodrive

- F Series - Mechanical VRC - Owner's Manual with NORD Motordrive

- M Series - Mechanical VRC - Owner's Manual with Eurodrive

- M Series -Mechanical VRC - Owner's Manual with Nord Motordrive

-

Dimensional Schematics

- 21 Series CSI Spec - No Quick Connect

- 21 Series CSI Spec - Quick Connect

- 21 Series Hydraulic Lift - Cantilever Style - Dimensional Schematic

- 21 Series Hydraulic Lift - Straddle Style - Dimensional Schematic

- 21 Series, Cantilever, CAD Drawing

- 21 Series, Straddle, CAD Drawing

- B Series Box Lift - Dimensional Schematic

- Bi-Panel Swing Gate Dimensions

- Bi-Panel Vertical Gate Dimensions

- D Series CAD Drawing

- D Series CSI Spec - No Quick Connect

- D Series CSI Spec - Quick Connect

- D Series Hydraulic Lift- Dimensions Schematic

- DB Series CAD Drawing

- DB1 Series Package Handling Lift - Dimensional Schematic

- DB2 Series Package Handling Lift - Dimensional Schematic

- F Series 4-Post Mechanical Lift - Dimensions Schematic

- F Series CAD Drawing

- F Series CSI Spec

- M Series 2-Post Mechanical Lift - Cantilever Style - Dimensions Schematic

- M Series 2-Post Mechanical Lift - Straddle Style - Dimensional Schematic

- M Series CSI Spec

- M Series, Cantilever, CAD Drawing

- M Series, Straddle, CAD Drawing

- Single Panel Vertical Gate Dimensions

- Single Sliding Gate Dimension

- Single Swing Gate Dimensions

- Show all articles ( 12 ) Collapse Articles

-

Applications

-

Videos

-

Gate Installation Instructions

- 15709-0005 - Gate Installation - Sliding - Swing - Bi-Parting

- 15709-0014 - Gate Installation - Bi-Panel Vertical Acting

- 15709-0120 - Gate Installation - Floor Level Swing with Sliding Latch

- 15709-0126 - Gate Installation - Floor Level Bi-Swing with Sliding Latch

- 15709-0133 - Gate Installation - Motorized Single Vertical Acting

- 15709-0143 - Gate Installation - Motorized Bi-Panel Vertical Acting

- 15709-0156 - Gate Installation - Single Vertical Acting

- 15709-0157 - Gate Installation - Carriage Mounted Single Vertical Acting

-

Safety Data Sheets

- 15713-0001 - SDS, Lubriplate 930 AAA

- 15713-0002 - SDS, Mobil SHC 630, Standard Synthetic Oil

- 15713-0003 - SDS, MobilGear 600 XP 220, Standard Base Oil

- 15713-0004 - SDS, Shell Omala S4 GX 220, Gear Lubricant

- 15713-0007 - SDS, Paint, Enamel - PFlow Blue, Aerosol

- 15713-0008 - SDS, Exxon MobilGrease XHP 222 Special

- 15713-0011 - SDS, Paint, Fast Dry Acrylic Enamel, PFlow Blue

- 15713-0012 - SDS, Paint, Universal Primer, PFlow Primer II

- 15713-0014 - SDS, Hydraulic, Biodegradable, Clarion AW Oil 32

- 15713-0015 - SDS, Weld-Aid Brite Zinc B-100, Aerosol

- 15713-0018 - SDS, Shell Omala S2 G 220, Gear Lubricant

- 15713-0021 - SDS, Fast Cure Epoxy, Macropoxy 646 (Part A) Mill White

- 15713-0022 - SDS, Dow Corning Oil, Molykote L-1468FG, Synthetic Freezer Chain Oil

- 15713-0023 - SDS, Mobil SHC CIBUS 220, Synthetic Oil

- 15713-0026 - SDS, Eureka Fluid Film Aerosol, Corrosion Inhibitor

- 15713-0028 - SDS, Benz Oil DEXRON III, ATF Hydraulic Fluid

- 15713-0031 - SDS, Shell Omala S4 GX 150, Gear Oil

- 15713-0035 - SDS, Starfire Multi-Purpose ATF Dexron III/Mercon

- 15713-0036 - SDS, Clarion Food Grade Machinery AW 32, Hydraulic Oil

- 15713-0038 - SDS, Paint, Safety Yellow, Aerosol

- 15713-0039 - SDS, Paint, Safety Yellow, Enamel

- 15713-0042 - SDS, Roll-on Paint, PFlow Blue

- 15713-0043 - SDS, Mobil SHC Gear 220 Synthetic Gear Lubricant

- 15713-0044 - SDS, LPS Cold Galvanize BrightCoat Aerosol

- 15713-0045 - SDS, CRC Dry Graphic Lubricant

- 15713-0046 - SDS, Duraspar 130 Gray Primer

- Corothane Exterior Epoxy - Safety Data Sheet

- Corothane Exterior Epoxy Hardener - Safety Data Sheet

- Show all articles ( 13 ) Collapse Articles

PFlow Screw Lift Provides a Safe and Controlled Movement of Satellites

Man-made satellites orbit the earth at altitudes that can exceed 20,000 miles, typically transported by a rocket or space shuttle, the speed and path of which are precisely controlled in order to launch the satellite into the desired orbit.

Satellites at this altitude orbit the earth at the same speed in which the earth turns, hovering over the same spot on the earth’s surface at all times.

Precise movement is a way of life for satellites, and at a Boeing manufacturing facility just outside Los Angeles International Airport, the precision begins on the very first trip a completed satellite takes.

Los Angeles, California

Aircraft Manufacturing Plant

- Mechanical “Screw” Lift

- Lifts Loads up to 80,000 lbs

- 2’ Vertical Rise

- 2 Levels of Vertical Rise

- 2 FPM Travel Speed

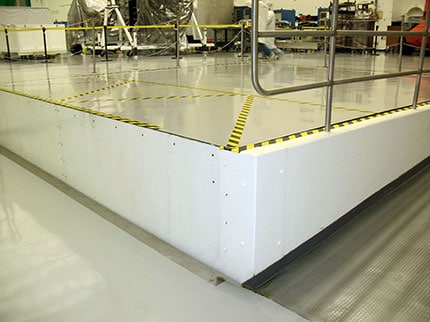

The trip, all of two feet, is from the assembly deck to the main floor on the platform of a custom designed vertical lift made by PFlow Industries.

The trip, all of two feet, is from the assembly deck to the main floor on the platform of a custom designed vertical lift made by PFlow Industries.

PFlow manufactures a wide variety of vertical lifts that move materials of varying sizes to and from heights that can exceed 200 sq. ft. Some are fairly standard, moving primarily boxes and pallets, while others are highly engineered, custom designed to move far more sensitive loads.

A screw lift was selected because it is able to achieve the precise movement required to safely transport the intricate and geometrically complex satellites. Screw lifts eliminate any subtle bounce or deflection that can occur with a hydraulic or mechanical lift. The Boeing lift also features an unusually large platform size and high payload, and travels a short distance relative to standard lifts.

The satellites made at the Boeing facility range in size from 10 – 20 sq. ft. in diameter, with heights up to 60 sq. ft. and weights up to 60,000 lbs. They are assembled in a cleanroom environment, and when complete are transported from the assembly deck to the main floor for testing. The lift fits flush within an existing pit on the main floor for easy loading and unloading. When testing is complete, the satellites are transported back to the assembly deck for modifications or preparations for shipping. Component parts are also transported by the lift.'

The four screws, which remain stationary during movement, are strong enough to support their share of the 80,000 lb. capacity of the lift. The two foot trip takes approximately two minutes in each direction, achieving a high level of stability.

Boeing Screw Lift Travel Accuracy

- Horizontal step displacements no more than 0.01” during vertical movement.

- Smooth horizontal translations (caused by straightness of travel) less than 0.02” over any 10’ of travel.

- Vertical positioning accuracy (difference between actual and commanded positions) less than 0.1” peak to peak and less than 0.05” RMS.

- Angular change of lift platform position about any axis less than 0.01° over any 1’ of travel.

- The vertical axis remains vertical within 0.01° in all operating conditions.

There are several sophisticated mechanisms that ensure and monitor the precise level of the lift platform. A variable speed drive is installed on each of the motors, ensuring that each motor starts and stops smoothly and moves at a steady, coordinated speed. The screws are also electronically synchronized by electric encoders on each motor to make sure the motors are in the same position on each screw, keeping the platform perfectly level.

Encoders with custom software communicate the position of each platform corner to verify the screws are in sync. If the screws become out-of-sync an audio alarm is triggered. Separate pitch-and-roll level sensors shut down the motors if it is not perfectly level, and corner guides provide structural stability.