Pick Module Replenishment

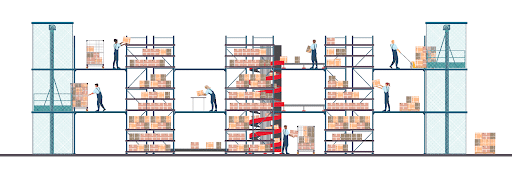

Vertical Reciprocating Conveyors (VRCs) can dramatically help improve the efficiency of your pick module system. They offer a versatile and cost-effective way of increasing the overall performance of your order fulfillment operation.

We custom design each VRC and tailor them to your exact requirements. VRCs can be installed in your new warehouse or be engineered to work with existing pick modules. We can even create a VRC to work with Autonomous Mobile Robots (AMRs).

Improve labor efficiency and optimize pick module replenishment with a VRC from PFlow.

Safe

PFlow designs our VRCs with safety first in mind. Pressure switches, mechanical stops, and safety cams are just a few of the many standard safety features

Value-Added

We work closely with our customers to understand their challenges and provide intelligent solutions that add value to their operations.

Customizable

Our team of engineers will design a highly customized solution that meets your exact operating environment and requirements.

Why Use VRCs in Pick Module Systems?

VRCs offer a wide array of features that make them perfect for use with pick modules:

- VRCs are perfect for working in tandem with new or existing horizontal conveyor systems

- VRCs are compatible with Autonomous Mobile Robots (AMRs)

- VRCs can be designed for continuous, 24/7/365 use

- VRCs provide a safer and more efficient material lifting means when compared to labor-intensive solutions such as forklifts, scissor lifts, or using stairs

Find the Perfect VRC for Your Pick Module Replenishment System

Lift loads from 10 lbs to 50,000 lbs or more with PFlow’s mechanical vertical reciprocating conveyors. Our VRC solutions have improved workflow efficiency and throughput in a wide array of warehouse and distribution center applications.

F Series (50,000 lbs+)

The 4-Post F Series mechanical lift (VRC) can easily handle loads of 50,000 lbs and can be customized to lift 200,000 lbs.

- Unlimited carriage size

- Unlimited vertical rise

- Standard travel speed of 18 FPM, with 400 FPM possible

- Unlimited cycles per hour/day

- Indoor or outdoor use

M Series (10,000 lbs)

The 2-Post M Series mechanical lift (VRC) can safely lift loads up to 10,000 lbs to any number of floor levels.

- Carriage size up to 12’ x 10’

- Unlimited vertical rise

- Standard travel speed of 25 FPM, with 400 FPM possible

- Unlimited cycles per hour/day

- Indoor or outdoor use

Engineered for your Specific Requirements

At PFlow, we create highly customized VRC solutions that solve your toughest pick module replenishment challenges. VRCs can be placed within and at the ends of pick modules and can be constructed to work within an existing structure.

Why PFlow?

Along with serving as a key author of state and federal codes relating to material lifts, PFlow Industries is the leader in material lifting solutions research and development, resulting in numerous patents for material lifts and related products.

Our engineering team is the largest in the industry. PFlow continues to create breakthroughs in vertical lift performance and safety with a culture focused on innovation.

Since our founding, we have built more than 20,000 VRCs with installations worldwide – many for very unique applications.

“We had the pleasure of working alongside PFlow Industries at the PROMAT 2019 show in Chicago. Chuck Cobb and his team are a devoted group of professionals dedicated to their craft! We look forward to working with them for years to come!”

– Rebecca S.

Frequently Asked Questions

A vertical reciprocating carrier (VRC) is also known as a material lift, and it safely lifts materials, boxes, and cargo from one floor level to another. People are not allowed to ride on VRCs. Mechanical and hydraulic are two different types of VRCs, and each has its own advantages and best use cases.

Our fully automated VRCs operate at a standard 25 feet per minute, and they are capable of reaching speeds of up to 400 feet per minute.

No! Mechanical VRCs from PFlow can reach unlimited floor levels.