Vertical Reciprocating Conveyors (VRCs)

PFlow Industries hydraulic and mechanical VRCs are a safe and efficient way to lift materials. We custom-engineer our material lifts to meet your size, space, and lifting requirements. We build industrial vertical lifts for a wide range of industries and applications to solve your toughest material lifting challenges.

Let our VRC experts help you determine the right vertical conveyor for your application.

Mechanical VRCs

Mechanical lifts are an efficient way to move loads of multiple pallets, oversized materials, large carts, or heavy machinery. These lifts can easily handle heavy loads and are ideal for high-speed, high-cycle, or automated systems.

- Straddle or cantilever configurations

- Smooth carriage travel and stops

- Standard travel speed between 18-25 FPM

- Multiple load configurations available

- Continuous cycle use

- Virtually unlimited load capacity

Hydraulic VRCs

Hydraulic lifts offer an affordable and efficient option for two-level lifting. PFlow Hydraulic Lifts are engineered for level carriage movement and stability, and are suited for indoor or outdoor use.

- Straddle or cantilever configurations

- Typically take up less space than mechanical VRCs

- Standard travel speed between 17-24 FPM

- Cost-effective lifting solution

-

Ability to lift loads up to 6,000 lbs

Vertical Reciprocating Conveyors (VRCs)

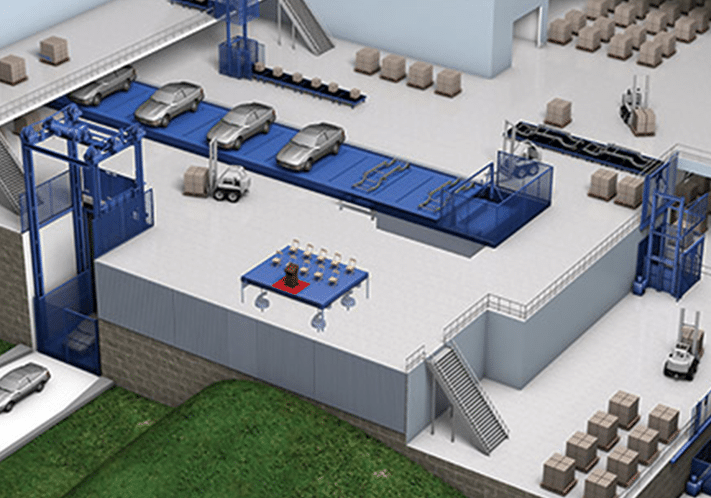

Vertical reciprocating conveyors (VRCs) are a safe and economical way to raise and lower materials. You can install them in a wide range of buildings, including:

- Factories

- Warehouses

- Distribution Facilities

- Industrial Plants

- Institutions

PFlow industrial vertical lifts are ideal for lifting products or supplies between floor levels. Our material lifts can be installed indoors or outdoors and can be incorporated into new construction or existing facilities.

Industrial vertical lifts are not elevators and can not be used to transport people. They have their own national safety code (ASME B20.1) and are specifically exempt from the national elevator code. In 1981, PFlow helped change the national safety codes to exempt “material-moving” vertical conveyors from “people-moving” elevator safety regulations.

See our state-by-state list of codes regulating VRC installation and use.

Vertical Conveyor Safety

PFlow takes vertical lift safety seriously. This is why we have an unwavering commitment to safety through our internal R&D program. Our expert engineers perform rigorous testing to develop and implement safety features in all of our material lifts.

We also offer optional safety features, such as:

- DeckLock Safety System

- Maintenance Pins

- Explosion-Proof Components

Vertical Reciprocating Conveyors Benefits

- Economical, space-saving solution to move materials, especially when compared to inclined conveyors and traditional elevators

- Advanced, patented safety features protect workers and materials

- Safer and more efficient than using a forklift to move materials between multiple levels

- Easily moves loads of all shapes, sizes, and weights

- Customized to exact needs for mezzanines, through-floor, and other multi-level applications

- Hydraulic, mechanical, package handling, and fully automated systems available

- Can be installed in an existing elevator shaft, through a floor, or in a new or existing building

- Less costly to install, operate, and maintain than elevators

- Guaranteed code approval in every state

- Conforms to ASME B20.1 Safety Standards

VRCs Designed for Your Specific Needs

The award-winning engineering team at PFlow Industries has unparalleled experience in the material lift industry. Their technical know-how enables them to solve your toughest vertical material lifting challenges.

PFlow has custom-designed material-handling vertical conveyors to move loads weighing 10 pounds to more than 100,000 pounds. Our material lifts have carriages ranging from 30” x 30” to 60’ x 60’, and vertical heights from 4’ to more than 200’.

Whether you are moving pallet loads of material or heavy equipment, the structural support and enclosed carriage framework of our vertical conveyors prevents loads from falling. This makes moving materials with our vertical lifts a safer and more efficient alternative to forklifts or scissor lifts.

We scrutinize and address every detail of each project to design and manufacture custom material lifting equipment for your specific application. Our expert engineers cover all design and construction issues, provide complete code-approved engineered drawings, and our in-house customer support team delivers exceptional ongoing service and support.

Our focus is, and always has been on safety, advanced technology, and creating solutions for specific vertical material handling challenges.

VRC Product Selector Guidelines

The following table should be used only as a guideline in determining which PFlow lifting conveyor is right for your application. Weight capacity is based on carriage size and added options. PFlow has designed vertical reciprocating conveyors (VRCs) to lift materials that weigh 10 pounds to more than 100,000 pounds. If you have application questions, please call us in Milwaukee at 1-414-352-9000.

| MODEL | M SERIES | F SERIES | 21 SERIES | D SERIES | B SERIES | DB SERIES |

|---|---|---|---|---|---|---|

| Type | Mechanical | Mechanical | Hydraulic | Hydraulic | Mechanical | Mechanical (automated with carriage conveyor) |

| Carriage Size | Up to 12' W x 10' L | Minimum 6' W x 6'6" L | Up to 12' W x 10' L | 6' W x 6' L | 3' W x 3' L (standard 3' load height) | 3' W x 3' L |

| Configuration | 2-Post Cantilever or Straddle | 4-Post | 2-Post Cantilever or Straddle | 2-Post Cantilever | 4-Post, Formed Steel Frame | 2-Post Cantilever |

| Capacity (lbs) | Up to 10,000, based on carriage size | Unlimited | Up to 6,000, based on carriage size | Up to 3,000, based on carriage size | 500 | 100 (Small Packages) |

| Vertical Rise | Unlimited | Unlimited | Up to 22' | Up to 15' | 15' 9" Floor-to-Floor (30" elevation at each level) | Standard Up to 20' |

| Levels | Multi | Multi | 2 | 2 | 2 | Multi |

| Standard Speed | 25 FPM | 18 FPM | 24 FPM | 17 FPM | 30 FPM | 60 FPM |

| Speed Upgrade | Up to 400 FPM or More | Up to 400 FPM or More | 30 FPM | 25 FPM | – | Up to 400 FPM or More |

| Cycles | Unlimited - Continuous | Unlimited - Continuous | 10/Hour - 100/Day | 10/Hour - 100/Day | Unlimited - Continuous | Unlimited - Continuous |

“Not only was PFlow able to design a custom downlift and uplift solution that fit our needs, but the company also engineered the entire moving-floor assembly system, based on our initial design concept, then manufactured and installed it.”

– David Konopacki, Lead Engineer, Bourgault

VRC Applications

- Freight

- Pallets

- Mezzanines

- Materials

Industries Served

Vertical Reciprocating Conveyor FAQ's

Don’t see your question below? Contact us to get help.

PFlow Industries offers hydraulic lifts and mechanical lifts for material handling. Both straddle and cantilever styles are available, along with four-post and modular designs. We customize our lifts for specific needs.

A mechanical lift is used where larger carriages are needed, the vertical rise is greater than 22′, or requires three or more level stops.

We suggest discussing your application with a PFlow representative or authorized dealer to ensure the proper lift is specified.

The carriage of a PFlow vertical lift is supported by wide flange columns. The columns need to be lagged to a ground level or surface. The columns are required to be braced at the upper levels and typically attached to the floor’s support structure.

The profile of a typical VRC carriage is 3″ to 10″ when mounted on the surface. When a flush first-level transition is required, a pit is needed, ranging from 4″ to 12″ and up.

Vertical lift dimensions vary by model. Please refer to CAD drawings located in the Knowledge Base for exact dimensions, or contact a PFlow representative or dealer to discuss your vertical material handling situation.

The motor pump for a typical hydraulic lift is 20″ wide x 30″ long x 20″ high. It can be mounted anywhere within 15′ of the lift. On a mechanical lift, the power unit is located at the top of the guide rail columns. It requires approximately 3′ of space above the carriage load height.

A mezzanine backstop safety panel (MBSP) is a fixed guard used at the upper level where there is a snap chain or drop bar, but no railing on the backside of the carriage.

These safety panels are used primarily on two or 90° load patterns for an edge of mezzanine application.

The panel attaches to the guide rail columns of the lift at the upper level.

Its purpose is to enclose the back of the carriage so that there is no possibility of someone walking onto the lift carriage and falling off, and to help prevent products from falling while loading at the upper level.

Safety gates and enclosures are intended to meet OSHA, ANSI, ASME and common sense standards. Anywhere a person can come in contact with a vertical conveyor lift, an enclosure guard is required. Where the lift is to be loaded, a safety gate with an interlock is required.

An interlock prevents a gate from being opened unless the lift is present at that level. The interlock also prevents the lift from running when the gate or door is not closed.

All electrical components needed to make the lift function are included with the vertical reciprocating conveyor. The standard controls are self-maintained contact controls. Constant pressure or dead-man controls are also available.

Approval drawings are typically prepared and sent out within two-three weeks after the receipt of an order for a material handling product from PFlow Industries.

Standard lifts are typically shipped 14 to 16 weeks after the signed approval drawing is returned to PFlow Industries.

The lift is typically shipped via common carrier. The major components in the shipment

- Carriage

- Guide columns approximately 20′ (dependent on vertical rise and splicing)

- Parts crate

- Drive base (mechanical) or power unit (hydraulic)

- Control panel

The basic steps for installing a lift:

- Columns are set in place and temporarily braced

- The carriage is placed between the columns and attached

- For mechanical lifts, the drive base must be raised to the top of the columns and attached

- Gates are assembled, set in place, anchored, and braced

- Enclosures are assembled, set in place, and anchored

- Wiring of electrical components

Standard preventative maintenance of a lift is typically within the capabilities of plant maintenance personnel.

- Inspect the lift on a quarterly basis

- Lubricate lift parts as required

See our Knowledge Base for maintenance documents.