What Are Vertical Reciprocating Conveyors (VRCs)?

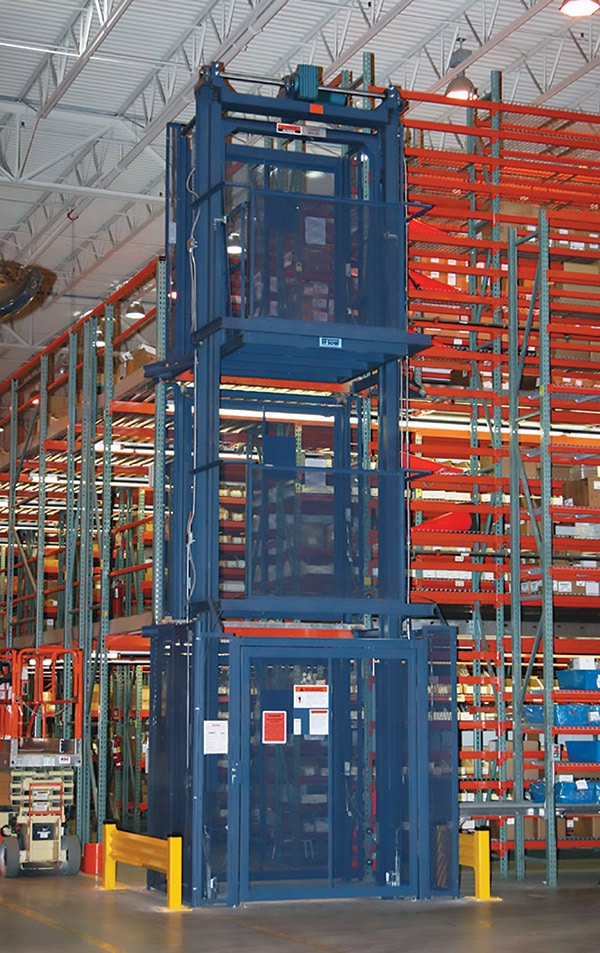

Vertical reciprocating conveyors (VRCs) are a safe, economical way to raise and lower materials in factories, warehouses, distribution facilities, industrial plants, institutions, or anywhere that products or supplies need to be moved from one level to another.

VRCs are not elevators and must not be used to transport people. They have their own national code (ASME B20.1) and are specifically exempt from the national elevator code. In 1981, PFlow helped change the national safety codes to exempt “material-moving” vertical conveyors from “people-moving” elevator safety regulations. (See our state-by-state list of codes regulating VRC installation and use.)

Material Lift Efficiency

Material lift vertical reciprocating conveyors provide fast, efficient and convenient access to and from mezzanines, balconies, basements, and between levels in multiple-story buildings.

These freight lifts can be installed for through-floor within a building, in an unused elevator shaft, or in interior/exterior applications.

The principal components of VRCs include guide columns, a carriage, and a mechanical or hydraulic actuating mechanism.

Custom VRCs – Designed for Your Specific Needs

The award-winning engineering team at PFlow Industries has unparalleled experience in the VRC industry, and has technical know-how to solve a myriad of vertical lifting problems. We have the knowledge and experience to build a custom VRC for your exact needs.

PFlow has custom designed material handling vertical conveyors to move loads that weigh only 10 pounds to more than 100,000 pounds. Our lifts have carriages ranging from 30” x 30” to 60’ x 60’, and vertical heights from 4’ to more than 200’.

VRCs are commonly used as vertical pallet lifts. As such, they transport pallet loads much more safely and efficiently than fork lifts.

We have built large-load work platforms, over-and-under equipment for assembly lines, hopper transfer systems, and much more.

At PFlow, we know each cargo lift application is unique. That’s why we scrutinize and address every detail of every job to manufacture a custom VRC for your exact situation. We carefully analyze your needs, cover all design and construction issues, provide complete code-approved engineered drawings, and deliver ongoing service support.

Our knowledgeable sales staff and engineers will design a customized vertical lift product tailored to your needs. Our focus has always been on safety and advanced technology – and creating solutions for specific vertical material handling problems.

Vertical Reciprocating Conveyor Benefits

There are many benefits to using a custom VRC to lift and lower materials from one level to another:

- Economical, space saving solution to move materials, especially when compared to inclined conveyors

- Advanced, patented safety features protect workers and materials

- Safer and more efficient than using a forklift to move materials between levels

- Conveniently move loads of all shapes, sizes, and weights

- Customized to exact needs for mezzanines, through-floor, and other multi-level applications

- Hydraulic, mechanical, package handling, and fully automated systems available based on lifting capacity needs

- Can be installed in an unused elevator shaft, new or existing building

- Less costly to install, operate, and maintain than elevators

- Guaranteed code approval in every state

- Conforms to ASME B20.1 Safety Standards

Contact our vertical material handling experts to discuss a vertical conveyor perfect for your application. Call us in Milwaukee at 414-352-9000, or use our Quick Contact Form.