Material lifts, otherwise known as vertical reciprocating conveyors (VRCs), are powered by either hydraulic or mechanical means. While both allow your business to move freight and materials from floor to floor more efficiently while improving safety and increasing productivity, one is not inherently better than the other. Each type of VRC has specific features that are best suited for certain lifting applications.

When considering a VRC for your lifting application, it is important to understand the features, advantages, and benefits of both types of lifts to help you make aninformed buying decision. Read on to learn more about the differences between mechanical and hydraulic lifts.

Hydraulic Lifts

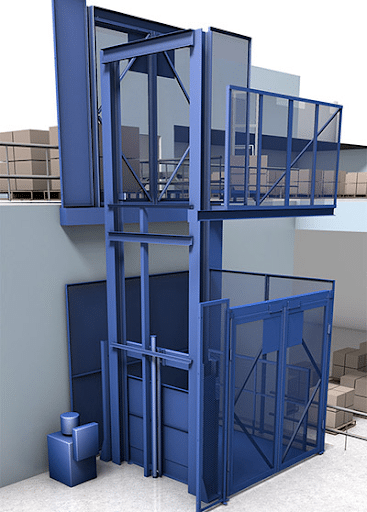

Hydraulic lift systems use compressed fluid that generates power to lift objects, materials, and supplies to a second floor, balcony, or mezzanine level. These lifts are available in cantilever and straddle configurations. Cantilever configurations mean the lift’s carriage is supported by two upright beams at one end of the carriage, providing three loading and unloading options. In straddle configurations, the lift’s carriage is supported between the lift’s upright or support beams, and allows for two loading and unloading patterns.

Hydraulic lift systems use compressed fluid that generates power to lift objects, materials, and supplies to a second floor, balcony, or mezzanine level. These lifts are available in cantilever and straddle configurations. Cantilever configurations mean the lift’s carriage is supported by two upright beams at one end of the carriage, providing three loading and unloading options. In straddle configurations, the lift’s carriage is supported between the lift’s upright or support beams, and allows for two loading and unloading patterns.

Hydraulic lifts are typically less expensive to purchase and install than mechanical lifts, and although both types of lifts offer safe and efficient vertical lifting options, each has specific attributes that make them a better choice than the other for certain lifting applications.

If your lifting application requires moving materials to a second level that is between 15’ and 22’ above the floor, and you do not require continuous lifting cycles, a hydraulic lift may be the right option for you. Hydraulic lifts are limited to 10 cycles/hour and 100 cycles/day and have lower payload capacity than mechanical lifts. In addition, due to the toxicity of hydraulic fluid, the use of hydraulic VRCs are prohibited in some environments.

How Does a Hydraulic Lift Work?

There are five main components of a hydraulic lift system:

- Pump

- Motor

- Oil tank

- Cylinder and piston (often referred to as a “Ram”)

- Pressure Compensated Valve

Hydraulic lifts are powered by a remote-mounted electric pump motor that actuates and transfers hydraulic fluid from the reservoir to the lift’s cylinders, basically raising the energy level of the fluid by increasing its pressure. This pressure creates the energy to move the lift’s carriage and its payload upward. To lower the lift’s carriage, a pressure compensated control valve regulates the flow of hydraulic fluid back into the reservoir, allowing the carriage to be lowered at a controlled and consistent speed under any load weight.

Benefits of a Hydraulic Lift

Hydraulic lifts come with a wide range of benefits, such as:

- Cost-effective solution for two-level lifting applications

- Available in cantilever and straddle configurations for a variety of loading/unloading configurations

- Typically lower initial installation cost when compared to a mechanical lift

- Cost-effective alternative to more expensive elevators

- Can be installed indoors or outdoors

Read More: Hydraulic Lifts 101: Pros and Cons

Mechanical Lifts

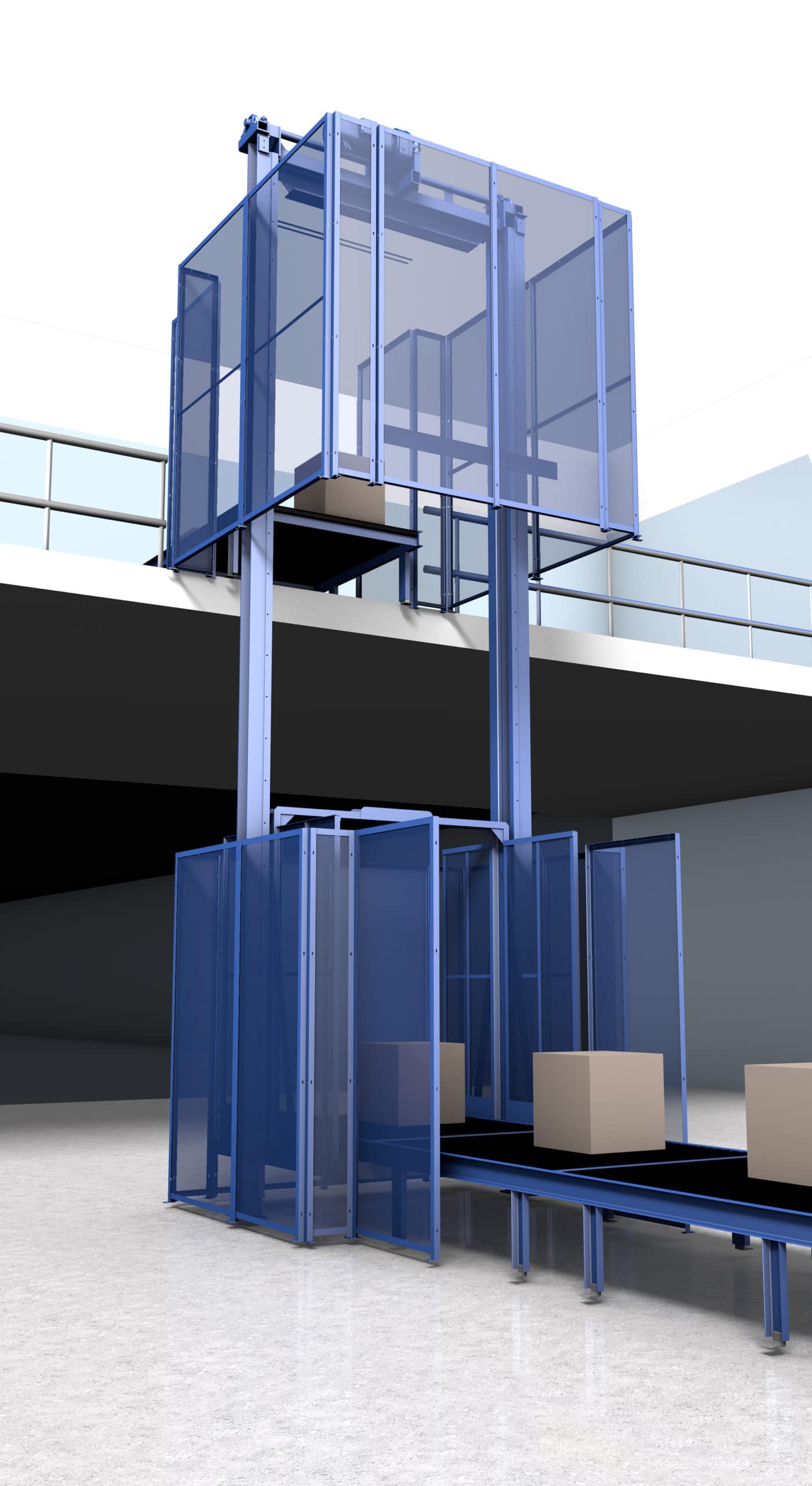

Unlike hydraulic lifts that use compressed fluid to generate the power to lift the lift’s carriage and payload, mechanical lifts are lifted and lowered by heavy-duty roller chains or cables and a gear reducer assembly. In general, mechanical lifts provide a smoother ride than hydraulic lifts, helping to significantly reduce the risk of damage to materials.

Like hydraulic lifts, mechanical lifts are available in cantilever and straddle configuration. Unlike hydraulic lifts, mechanical lifts are also available in a 4-post configuration that provides 360-degree access for loading and unloading, which can be key to improving material handling efficiency.

While typically more expensive than hydraulic lifts, mechanical lifts can do what hydraulic lifts cannot. Mechanical lifts can reach an unlimited number of floor levels, have unlimited cycle use, making them perfect for high-speed, high-capacity, or automated applications, and can lift far heavier payloads than hydraulic lifts. It is important to weigh the pros and cons because although mechanical are typically more expensive to manufacture and install than hydraulic lifts, mechanical lifts are less costly to operate and maintain than hydraulic units.

How Does a Mechanical Lift Work?

A system of heavy-duty roller chains and sprockets attached to a synchronized mechanical lifting mechanism powers the smooth vertical movement of a mechanical lift’s carriage. An electric motor attached to the cables allows for a controlled ascent or descent of the carriage.

Benefits of a Mechanical Lift

Mechanical lifts offer several distinct advantages, such as:

- Lower total lifetime cost when compared to a hydraulic lift

- No risk for hazardous, accidental, or messy fluid spills

- Unlimited cycle use

- Ideal for high-speed, high-capacity, continuous or automated applications

- Available in cantilever, straddle, and 4-post configurations for a wide range of loading/unloading patterns

- Virtually unlimited rise and lifting capacity

Read More: 5 Benefits of Using a Vertical Material Lift

Total Cost of Ownership

Safety Features of Hydraulic and Mechanical Lifts

While each manufacturer is different, the mechanical and hydraulic lifts offered by PFlow come with the following standard safety features like:

- Safety cams (that prevent sudden carriage descent in the unlikely event of a lifting chain break)

- Limit switches or velocity fuses that stop uncontrolled carriage descent when power is lost

- Rugged enclosures that help protect materials and workers

- Safety gates (sliding, vertical acting, and swing designs available)

Comparison of Hydraulic and Mechanical Lifts

| Hydraulic Lift | Mechanical Lift | |

| Cycles Per Day | Up to 10 cycles per hour / 100 cycles per day | Unlimited |

| Lifting Weight Capacity | Up to 6,000 lbs | 200,000 lbs + |

| Noise Levels | Can have a noticeable noise as the hydraulic cylinder presserize | Very low noise levels |

| Indoor or Outdoor Use | Both | Both |

| Smoothness of Travel | Stops are much more abrupt than mechanical | Very smooth |

| Suitable for Use in a Wide Variety of Environments | The hydraulic oil used to operate the lift could potentially leak, making hydraulic lifts unsuitable for clean room, food and other sterile environments | Yes |

| Maintenance Requirements | Often requires more maintenance than mechanical lifts due to hydraulic parts/oil/hoses/etc | Standard maintenance |

Which Lift is Right For You?

Mechanical and hydraulic lifts both have the potential to improve the way you vertically transport materials. However, it’s essential to understand the specific needs of your business so that you can make an informed decision about what lift is right for you.

At PFlow, each of our vertical reciprocating lifts are customized for your application. Our engineers can help you solve your toughest material movement challenges with innovative solutions. Learn more about our lift options below.