7 Tips to Optimize Material Flow in a Multilevel Warehouse

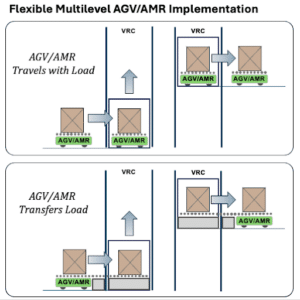

7 Tips to Optimize Material Flow in a Multilevel Warehouse Vertical reciprocating conveyors (VRCs) provide a right-sized, tailored lifting solution for multiple warehouse applications, opening