Aeronautics & Aerospace VRCs

High-value and mission-critical parts and assemblies need to be handled with the utmost care. A vertical reciprocating conveyor (VRC) is the ideal solution for moving sensitive equipment and material between levels.

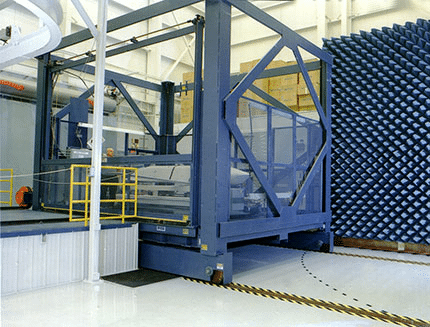

A VRC uses controlled motion to raise or lower delicate assemblies without jarring, vibration, or risk of damage and helps minimize movement through a factory by accommodating the changes in level that sometimes exist between assembly and test areas.

VRCs enclosed carriage structure is well-suited for moving sensitive materials between floor levels compared to cranes and fork trucks. VRCs also simplify and make your material handling process more efficient. The VRC was pioneered by PFlow Industries and our expertise is second-to-none. Each PFlow VRC is designed specifically for your lifting application.

Features of PFlow Vertical Reciprocating Conveyors

Our VRCs can be engineered for any load capacity, platform size, or vertical lift required. They can be installed as a through-floor VRC, in an unused elevator shaft, next to a balcony or mezzanine and, in indoor or outdoor applications. Standard and available features include:

When applications demand especially precise motion control PFlow can meet the challenge. Read more how PFlow engineered a VRC to meet the exacting standards required in the satellite manufacturing process.

Note that while PFlow guarantees code approval in every state, a VRC is a form of conveyor and cannot be used for transporting people.

Benefits of PFlow Vertical Reciprocating Conveyors

PFlow VRCs are engineered to suit the specific application requirements. This ensures space and layout constraints are met while satisfying requirements for safe, risk-free movement between levels. Benefits reported by users in the aerospace sector include:

- Easier and faster lifting than when using cranes

- Minimal vibration compared to moving items by fork truck

- Less risk of damage as shocks and impacts are avoided

Aeronautics & Aerospace Material VRC Applications

Aeronautics and aerospace manufacturers have much in common with those in other industries. Common manufacturing applications for VRCs include:

- Moving components and materials to and from multiple floor levels

- Moving cartons, cases, and individual parts between floors for packaging and shipping operations

- Moving pallets in and out of storage

Where lifting requirements differ from other industries is in the need for smooth travel and stopping for lifting of sensitivity of materials and the precision with which materials must be loaded and unloaded.

Aerospace material VRC applications where PFlow has been involved include:

- Moving large structures between clean room assembly and test chambers

- Moving missiles between assembly and test

- Transporting satellites into final assembly

Aeronautics & Aerospace Material VRC Testimonials

“Initially, our plan was to move the missiles horizontally into the chamber with an overhead crane. Then, the missile would be placed on a lift that would move it vertically to a designated testing station. This initial concept, however, proved to be too costly and inefficient.”

– Michael P. Goeb, Director of Major Projects at Lockheed Martin Missiles and Fire Controls

Vertical Reciprocating Conveyor FAQs

Don’t see your question below? Contact us to get help.

It depends on the model. Our F and M series VRCs have no vertical rise limit. Others are restricted to 22’ or less.

Yes! Our B Series Box Lift sounds ideal. It will save your employees time and reduce the risk of injuries or product damage.

This depends on your state. Our website has state-by-state information on Codes relating to VRCs.

Aeronautics & Aerospace Material Vertical Reciprocating Conveyor Resources & Case Studies

Improve Handling of Aeronautics & Aerospace Components and Assemblies

If you need to transport high-value, mission-critical products, we can help. Ask for a free quote for a vertical conveyor designed specifically for your application. Call us in Milwaukee at 414-352-9000, or use our Quick Contact Form.