Hydraulic VRCs

PFlow hydraulic lifts use compressed fluid to generate power to lift materials in 2-level lifting applications. PFlow's hydraulic VRCs lift loads from 10 lbs to 6,000 lbs and can accommodate 10 cycles per hour, 100 cycles per day. All PFlow Hydraulic lifts come with a lifetime structural warranty.

Let our VRC experts help you determine the right hydraulic VRC for your specific application.

21 Series

Hydraulic VRC

The 21 Series hydraulic lift (VRC) from PFlow Industries is a two-post hydraulic lift that can handle loads of up to 6,000 pounds, based on the carriage size and added accessories.

- 6,000 lbs load capacity

- 12’x10’ standard carriage size

- 22’ vertical rise

- Standard travel speed of 24 FPM

- 10 cycles per hr. / 100 cycles per day

- Straddle or cantilever configuration

- Indoor or outdoor use

D Series

Hydraulic VRC

The D Series hydraulic lift (VRC) from PFlow Industries lifts loads of up to 3,000 pounds, based on carriage size and added accessories, and has an innovative design that ensures highly stable loading and unloading.

- 3,000 lbs load capacity

- 6’x6’ standard carriage size

- 15’ vertical rise

- Standard travel speed of 17 FPM

- 10 cycles per hr. / 100 cycles per day

- Indoor or outdoor use

Need Help Deciding?

PFlow Industries manufactures vertical reciprocating conveyors to solve any material lifting need. Use our configurator to find the perfect lift for your application, and then we’ll design it to your exact requirements.

“I was amazed at how fast and easily it went in. For this building and its age, the process went very smoothly.”

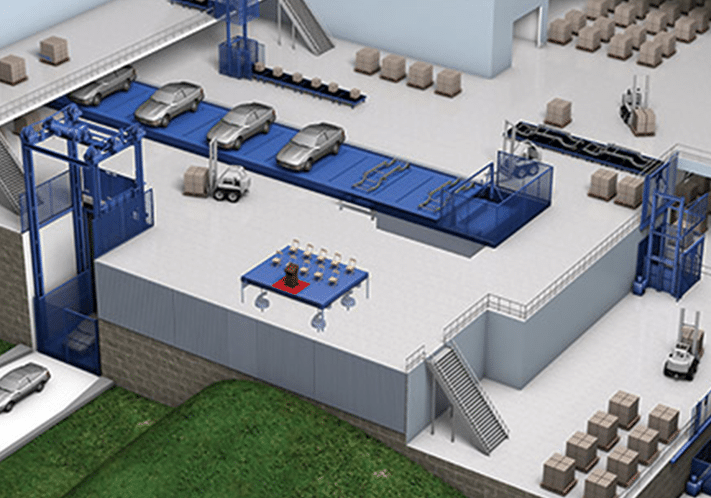

VRC Applications

- Freight

- Pallets

- Mezzanines

- Materials

Industries Served

Vertical Reciprocating Conveyors (VRCs)

Don’t see your question below? Contact us to get help.

We offer a wide range of package handling and VRCs that can lift anywhere from 100 to 200,000 lbs. Each lift comes with several essential features, such as:

- Safety gates (swing, sliding, and vertical acting designs)

- Enclosures to protect both workers and materials

- Safety cams (to prevent carriage descent in the unlikely event of a lifting chain break)

- DeckLock safety system

Hydraulic lifts offer a wide range of benefits, such as:

- Lower initial cost to install than a mechanical VRC

- They’re a cost-effective solution for two-level lifting applications with limited cycle use.

- Compared to a mechanical lift, a hydraulic lift takes up less space.

- They’re a cost-effective alternative to elevators.

The lift dimensions vary depending on the model and your specific requirements. Please check out the CAD drawings in our Knowledge Base for precise dimensions or contact one of our knowledgeable PFlow representatives or dealers for more information.

Yes. ANSI, ASME, OSHA, and good old-fashioned common safety sense dictate that anywhere a human being can come into contact with a vertical conveyor lift, you will need an enclosure. A safety gate with an interlock mechanism is mandated at the loading point of the lift. Safety first.

- Hydraulic lifts have limited vertical rise and are therefore used in 2-level lifting applications. Mechanical lifts have unlimited vertical rise, allowing access to unlimited floor levels.

- Hydraulic VRCs have a lower initial cost but they require more ongoing maintenance than mechanical VRCs.

- A hydraulic lift has limited cycles per hour and per day and mechanical lifts are designed for unlimited use.

- Hydraulic VRCs are intended to lift up to 6,000 lbs payloads versus an almost unlimited payload capacity for mechanical lifts.

We typically prepare and send out approval drawings within two to three weeks after receiving an order for a material handling product. A standard lift has a general shipped lead time of 14 to 16 weeks after returning the signed approval drawing to PFlow Industries.

Payload capacity, vertical rise, and cycle use requirements are just a few of the many things you will need to consider when choosing the right vertical reciprocating conveyor. Check out the calculator on our Product Configurator page for a more detailed look at which hydraulic lift will best suit your application.

Hydraulic lift maintenance is dependent upon the model and configuration that you select. Generally speaking, in addition to visually inspecting the lift every month and replacing the hydraulic fluid as needed, you will need to change the hydraulic oil and oil filter once a year and replace all hoses and fittings every five years. For a more detailed look at maintenance requirements, check out the Preventive Maintenance section in the Knowledge Base.

No! Federal, state and local codes prohibit the transport of people within a hydraulic (or mechanical) VRC. Hydraulic lifts are only to be used for transporting materials.

There are six basic lift installation steps:

- Columns are set in place and temporarily braced

- The carriage is placed between the columns and attached

- Gates are assembled, set in place, anchored, and braced

- Enclosures are assembled, set in place, and anchored

- Wiring of electrical components (made easier when you select PFlow’s quick connect cabling option that pre-wires the push-button controllers, motor pump, and gate interlocks.