Is It Time to Upgrade to a Vertical Reciprocating Conveyor (VRC)?

Accidents or near misses? Materials piling up at a pinch point or getting damaged during transfer? Mounting maintenance or repair costs? Then it’s time to

Material Handling

Accidents or near misses? Materials piling up at a pinch point or getting damaged during transfer? Mounting maintenance or repair costs? Then it’s time to

When it comes to moving material loads between floor levels, not all solutions are created equal. While forklifts, inclined conveyors, scissor lifts, freight elevators, and

Injuries are, unfortunately, common for the employees who work in warehouses. The right machinery can be the difference between efficient warehouse operations and repeated worker

Warehouse space is expensive. Before expanding your space, make sure you’re making the most of what you already have. Even if you’re not out of

When you need to get materials from one level to another, there’s no better choice than a Vertical Reciprocating Conveyor (VRC). In addition to saving

Drones, intelligent conveyors, and racking systems that rise 40’ into the darkness. No, it’s not science fiction, it’s the future of warehouses and distribution centers.

Fully Automated Conveyor Systems Vertical reciprocating conveyors (VRCs) are a safe and efficient way to move materials between two or more levels. Automated conveying systems

PICK MODULE REPLENISHMENT OPTIMIZATION & SAFETY As consumer product demand increases, the pressure put on warehouses and fulfillment centers to replenish pick modules (and mezzanine

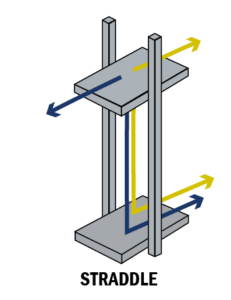

Material lifts, otherwise known as vertical reciprocating conveyors (VRCs), are powered by either hydraulic or mechanical means. While both allow your business to move freight

Tips for Setting Up a Safe and Efficient Operation Many factors go into picking essential equipment for a warehouse. Every business and warehouse are different,