PICK MODULE REPLENISHMENT OPTIMIZATION & SAFETY

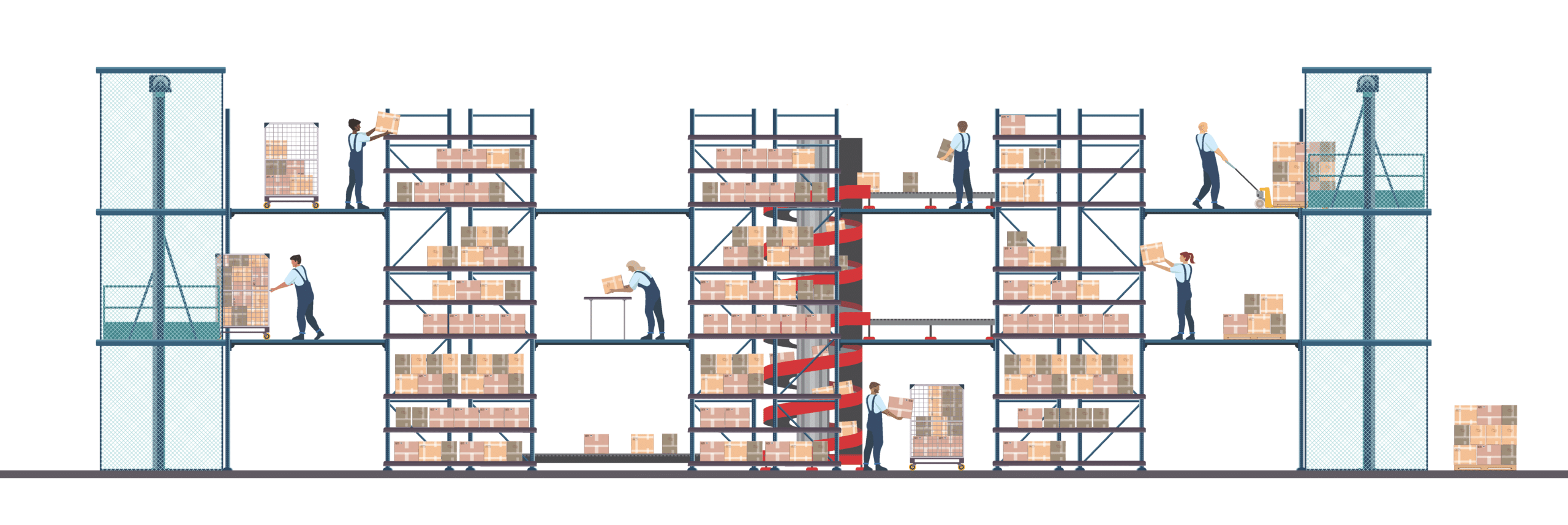

As consumer product demand increases, the pressure put on warehouses and fulfillment centers to replenish pick modules (and mezzanine areas) grows. Because of that, the need for safe and efficient vertical material movement solutions has never been more important.

IMPROVE YOUR PICK MODULE REPLENISHMENT PROCESS

Getting inventory to and from pick modules, mezzanines or multi-level storage solutions quickly and safely can be a labor-intensive process when using stairs, forklifts or scissor lifts.

PFlow vertical reciprocating conveyors (VRCs) remove your vertical lifting obstacles and provide a solution tailored for your application.

WHAT IS A VRC?

A VRC is a safe and economical way to raise and lower materials to two or more levels. Sometimes referred to as material lifts, VRCs provide fast and efficient access to multiple floor levels in various applications such as pick module levels, mezzanines and balconies and, are intended to lift materials, not people.

VRCs are not elevators and must not be used to transport people. They have their own national code (ASME B20.1) and are specifically exempt from the national elevator code. In 1981, PFlow helped change the national safety codes to exempt “material-moving” vertical conveyors from “people-moving” elevator safety regulations.

Installing a vertical reciprocating conveyor (VRC) in your warehouse or distribution center not only provides a safe and efficient way to move materials, it allows you to reach an unlimited number of vertical levels, allowing you to expand up and not out.

VRCs VS OTHER VERTICAL LIFTING MEANS

Not only do VRCs provide a safe and efficient vertical lifting solution they are generally less expensive to install and maintain than elevators and require no special training or certification to operate. Let’s take a look at some other VRC advantages:

- VRCs are compatible for use with new or existing pick modules or mezzanines and, are perfect for last-mile distribution centers that may be located in multi-level facilities.

- VRCs can be automated to work in tandem with horizontal conveyor systems

- VRCs are compatible with AMRs

- VRCs can be designed for continuous, 24/7/365 use

- VRCs feature enclosed carriages, preventing loads from falling

- VRCs cannot transport people and therefore, have their own code requirements (ASME B20.1) meaning:

- They can be installed where elevators cannot

- They do not require the same level of inspection or maintenance

- They move material loads faster than elevators

- They have higher load capacity than elevators

- VRCs allow you to take advantage of overhead space that cannot be reached by forklifts or scissor lifts

- PFlow VRCs are engineered to meet your specific lifting requirements

To learn more about how PFlow Industries VRCs can help your business maximize throughput without compromising safety, read more about our VRC options or, contact a PFlow representative to discuss your specific vertical lifting needs.