When you need to get materials from one level to another, there’s no better choice than a Vertical Reciprocating Conveyor (VRC). In addition to saving time and money, VRCs offer improved safety and efficiency versus moving pallets or goods by hand or forklift.

There are three main VRC configuration options:

- Straddle

- Cantilever

- 4-Post

Each option offers its own unique set of advantages and uses. Read on to learn more about vertical reciprocating conveyor design options and which one is right for your application.

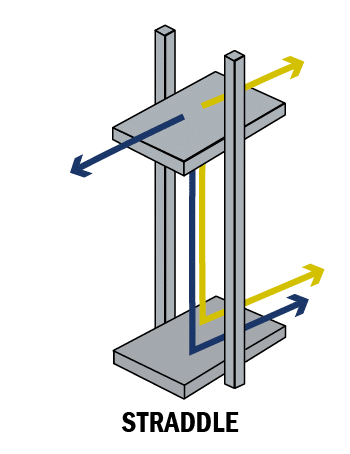

Straddle

In a straddle configuration, the VRC’s carriage is placed between the two guide columns, distributing the weight of the load vertically along the length of both columns.

This type of configuration allows for greater lifting capacity and larger carriage platform sizes than a cantilever configuration. It also accommodates higher rollover force, or the force created during loading and unloading of the VRC.

The straddle layout allows for C loading (load and unload from the front) and Z loading (load and unload on opposite sides) patterns and is a great option in applications that do not have space constraints and do not require unlimited load height.

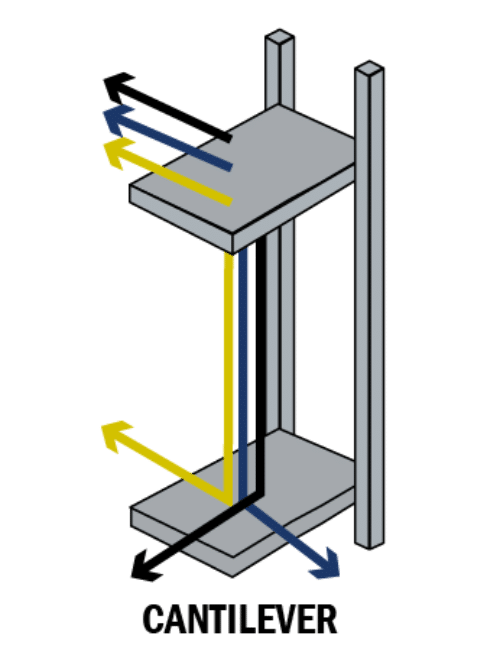

Cantilever

In a cantilever configuration, the VRC’s carriage is supported by two guide columns on one side of the carriage. This configuration allows easy access from three sides of the VRC and supports three load patterns; a C load pattern (load and unload from the front); a Z load pattern (load and unload from opposite sides); and, a 90 degree load pattern (load from the front and unload from the side).

Cantilever configurations allow for more loading and unloading flexibility to maneuver loads, especially in space constrained areas, and they can typically accommodate taller cargo than straddle configurations.

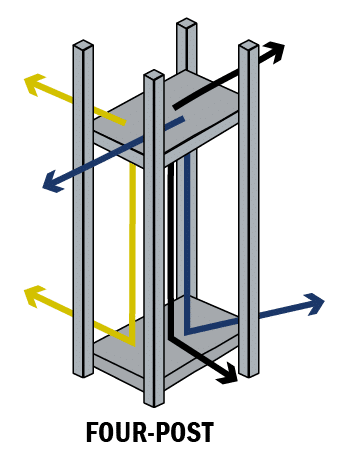

4-Post

The 4-post VRC configuration has the platform mounted within the four guide columns. This allows for maximum lifting capacity and large platform sizes.

4-post VRCs are well-suited for applications that require lifting and lowering large, bulky and/or oversized or extremely heavy loads. The configuration of the 4-post system also enables workers to load or unload from any size of the carriage for maximum flexibility.

Configuration Options for PFlow VRCs

PFlow offers VRCs in 2-post straddle, 2-post cantilever, and 4-post configurations:

Learn More About PFlow VRC Options

PFlow offers a wide variety of VRCs, each customized to meet the needs of your specific material handling application.

Click below to learn more about our vertical lifts, or contact us directly, and we’ll help solve your toughest of challenges.