Mezzanine lifts, also known as vertical reciprocating conveyors (VRCs), provide a versatile, reliable way to move materials between different levels within a facility. From warehouses and distribution centers to manufacturing plants and back-of-house retail spaces, VRCs simplify the vertical transportation of materials to and from mezzanines, allowing for seamless movement of heavy loads, improving safety, and increasing operational efficiency. When selecting a mezzanine lift for your facility, its load capacity is one of the most critical factors to consider.

In this guide, we’ll explore the factors that impact mezzanine lift load capacity and compare different lift models. By understanding the load capacity and customization options available,we can help you select the most suitable mezzaine lift for your material lifting application.

What Determines Load Capacity for Mezzanine Lifts?

Load capacity is the maximum weight a mezzanine lift can safely transport between levels. The right load capacity for your application depends on several factors:

- Lifting Mechanism: Different lifting mechanisms (mechanical versus hydraulic) have varying load capacities. Mechanically-driven mezzanine lifts support higher load capacities than hydraulically-driven mezzanine lifts.

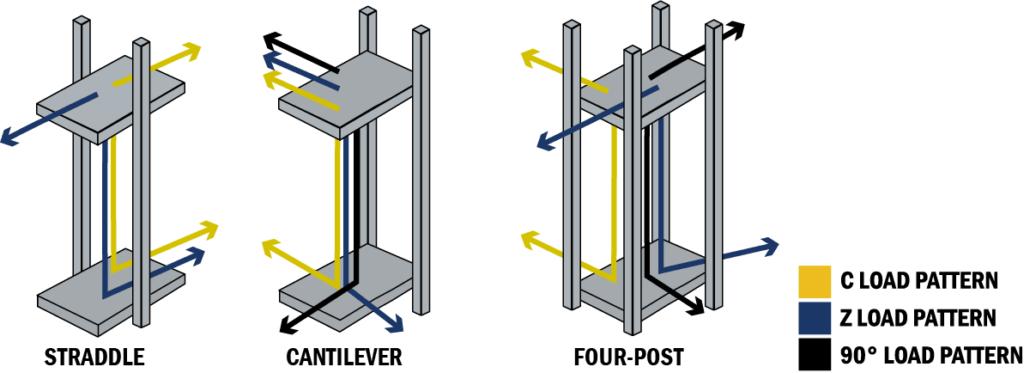

- Lift Configuration: Mezzanine lifts can be constructed in a straddle configuration (the lifting platform is placed between the upright columns) or a cantilever configuration (the lifting platform is supported by guide columns on one side). Straddle lifts support heavier loads because the load is evenly distributed, while cantilever designs offer more loading/unloading flexibility but can have lower overall lifting capacity.

- Customization: Added options, such as carriage-mounted gates, increase the carriage's total weight and count against the mezzanine lift's maximum allowable load capacity.

PFlow’s Top Mezzanine Lifts by Load Capacity

PFlow offers mezzanine lifts with various load capacities to cater to a wide range of material handling needs. Here are three of PFlow’s standout VRCs designed for mezzanine applications, each with its own capacity range:

D Series Hydraulic Mezzanine Lift

- Load Capacity: Up to 3,000 lbs

- Best Use: Engineered for limited cycle use in two-level lifting applications.

- Overview: The D Series Hydraulic VRC is designed to manage routine material lifting tasks efficiently. With a 3,000 lb capacity, it’s ideal for handling pallet loads and lighter materials, offering a robust and dependable vertical lift solution. This lift is perfect for facilities requiring frequent material transport to a second level, without the need for continuous heavy-duty operation.

Common Applications: Simple, two-level lifting applications; perfect for lifting pallet loads to a second level.

21 Series Hydraulic Mezzanine Lift

- Load Capacity: 6,000 lbs.

- Best Use: Engineered for limited cycle use in two-level lifting applications.

- Overview: The PFlow 21 Series Hydraulic VRC efficiently lifts up to 6,000 lbs to 22 feet. Its durable hydraulic system ensures smooth operation, with straddle or cantilever configurations for versatile use in manufacturing, warehousing, and distribution. Ideal for 2-level, heavy-duty material transport.

Common Applications: Manufacturing facilities, automotive dealerships, retail and commercial facilities, and food manufacturing facilities.

M Series Mechanical Mezzanine Lift

- Load Capacity: Up to 10,000 lbs

- Best Use: Designed for environments that require continuous cycle use and/or heavy-duty lifting.

- Overview: The M Series Mechanical VRC is engineered to deliver exceptional performance, offering a load capacity of up to 10,000 lbs. Its robust construction makes it an ideal choice for heavy-duty applications, including the frequent lifting of heavy materials in manufacturing plants and large distribution centers. Designed for consistent and reliable operation, this lift can be configured as either a straddle or cantilever system, providing flexibility to meet the specific needs of your facility.

Common Applications: Manufacturing facilities, automotive dealerships, retail and commercial facilities, distribution centers (including SLAM areas – the last 100 feet of the warehouse), food manufacturing facilities, automated conveyor systems integration.

Customizing Your PFlow Mezzanine Lift for Optimal Performance

One of the greatest benefits of choosing a mezzanine lift from PFlow is the flexibility to customize it to your specific needs. Our engineers work with you to design a lift that meets the exact specifications for your material handling needs, including:

- Carriage Size Customization: The dimensions of the carriage or, enclosed platform in which the materials travel, can be customized to accommodate a variety of load sizes, from smaller parcels to oversized pallets or equipment

- Configuration: Changes to your existing operation are minimized by selecting a VRC that accommodates your current space. It is important to understand how materials will be loaded and unloaded from the VRC and the space available at each floor level for this activity. Each type of VRC accommodates different loading patterns, (the direction(s) in which the VRC platform is approached for loading and unloading). The three options are:

- C: Load and unload from the same side of the carriage (creating a “C” shape when viewed in profile).

- Z: Load from one side of the carriage and unload from the opposing side (which maintains the same direction of movement).

- 90°: Loads from the front of the carriage and unloads from the side of the carriage.

Choosing the correct loading pattern is critical to ensuring you have the space needed to efficiently load and unload materials.

- Safety features: We offer a range of advanced safety features, including enclosures, gates, and our DeckLock Safety System, to protect your employees and ensure the secure handling of heavy loads.

Our approach to customization ensures that your mezzanine lift aligns with your workflow, maximizing efficiency and safety.

PFlow: Experts in Mezzanine Lift Solutions

Selecting the right mezzanine lift with the appropriate load capacity is crucial for operational success. With decades of experience in the industry, we have the expertise to guide you through the selection and customization process, ensuring your mezzanine lift meets your specific requirements.

Ready to explore mezzanine lifts that can take your material handling operations to the next level? Contact us to discover how our mezzanine lifts can enhance your facility’s workflow and efficiency.