Vertical reciprocating conveyors (VRCs) offer an efficient way of moving materials, pallets, and heavy objects from one floor level to another. VRCs significantly increase safety in busy work environments when compared to forklifts and other manual material moving methods, due to their enclosed carriage structures.

However, like all things heavy and mechanical, VRCs can present significant safety hazards if not designed with safety features such as safety cams, limit switches, and gates/enclosures.

PFlow Industries takes safety very seriously. Since day one, PFlow’s dedication to VRC safety research and development has ensured that our products meet and/or exceed code requirements. Our rigorous testing and robust R&D programs have led to several patented safety innovations that we incorporate into or offer as options on all of our VRC products.

Let’s review VRC safety features that help to safeguard people and materials.

Snap Chain

Diagonal Drop Bar

Safety Gates

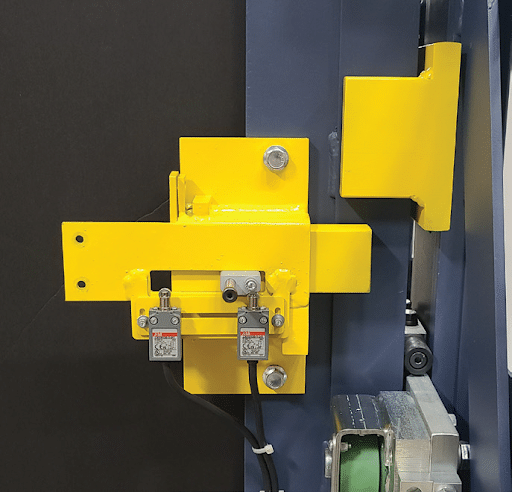

ASME B20.1 Code regulations specify that each VRC must be equipped with a safety gate that’s mechanically interlocked with the carriage movement. PFlow safety gates are space efficient, built for maximum protection and performance, and equipped with a mechanical lock and electric contact. All PFlow safety gates meet code requirements for manual loading applications.

We offer three different single, bi-parting, and bi-panel types of safety gates:

Swing

Sliding

Vertical Acting

Enclosures

Enclosure panels are required by code for all accessible sides of a VRC that are not used for loading or unloading. The enclosure must be at least 8’ high and capable of rejecting a ball 2” in diameter at each level. An enclosure panel is not required if a wall protects the side.

PFlow enclosure panels are 6” to 5’ wide and constructed out of ½” flattened expanded metal. We can design and manufacture non-standard sizes, custom finishes, and galvanized panels upon request.

Structural Steel

Chain Tensioner

Safety Cams

Twin Roller Guides

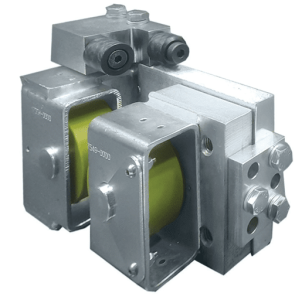

This safety feature helps ensure reduced carriage movement at floor levels and smooth chain spooling. Twin Roller Guides are standard on all M, MQ, 21 Straddle, and F Series lifts.

PFlow’s Twin Roller Guides are designed for ease of maintenance as each bearing-free, Nyloil® cast nylon roller wheel has built-in oil lubrication.

In addition to providing superior durability and performance compared to a traditional phenolic wheel with bearings, Nyloil® cast nylon roller wheels require less maintenance and installation time.

For extremely heavy loads, the Nyloil® Twin Roller Guides are replaced with steel guides.

Limit Switches

Velocity Fuses

On hydraulic VRCs, velocity fuses regulate the flow of hydraulic fluid in and out of the cylinders. This safety feature ensures that in the event of a hydraulic line break or cylinder failure, the flow of hydraulic fluid is limited to prevent uncontrolled carriage descent.

Overload Sensors

OPTIONAL SAFETY FEATURES

Maintenance Pins

Decklock Safety System

Maintenance Mode

PFlow leads the Industry in VRC Safety. Our innovative and robust safety features ensure safe material handling in factories, warehouses, industrial plants, or anywhere that goods need to be moved from one level to another. Our unwavering commitment to safeguarding workers and materials helps ensure a more secure material-handling experience.

Choose PFlow and enjoy peace of mind with our VRCs that are guaranteed to meet code in all 50 states. Click below to discover the value you’ll get with a PFlow material lift.