Overview: Why Customize the M Series Mechanical VRC?

The PFlow M Series Mechanical Vertical Reciprocating Conveyor (VRC) offers exceptional performance, unmatched reliability, and limitless customization. Whether your operation demands high lifting capacity, enhanced safety, or integration into automated conveyor systems, the M Series is built to your exact specifications.

If you're searching for a fully customizable material lift designed for heavy-duty, multi-level vertical transport, the M Series is your solution.

Built for Your Exact Requirements

Designed for adaptability, the M Series VRC is engineered to suit your specific material lifting needs:

- Unlimited Vertical Travel: Ideal for material movement between any number of floor levels, indoors or outdoors.

- Custom Carriage Sizes: Accommodates loads of virtually any shape or size, from pallets and parts bins to oversized machinery, the M Series carriages are custom built to meet your specifications.

- Heavy-Duty Lifting Capacity: Handles material loads up to 10,000 lbs with smooth, reliable operation. Precision controls allow for safe and stable elevation of light or heavy payloads.

- Built to Last: Built to handle continuous use in demanding environments, 24/7/365.

Whatever operational material lifting challenge you face, whether it is lifting oversized loads, operating within tight or limited space, or integrating with automated conveyor systems — the M Series VRC is engineered to adapt to your specific needs.

Advanced Customization Features

Enhanced Safety Features

Safety is non-negotiable in material handling operations. That is why the M Series VRC comes equipped with rugged, industry-compliant standard safety features and offers customizable safety enhancements tailored to your specific operational requirements. These optional safety features include:

- DeckLock™ Safety System — All PFlow vertical reciprocating conveyors (VRCs) are engineered to maintain carriage position under loads up to 150% of rated capacity as a standard safety feature. However, in high-risk scenarios—particularly when loading or unloading at upper levels using a forklift—PFlow’s DeckLock Safety System provides an additional failsafe against unintended carriage movement.

- Carriage-Mounted Safety Gates –Carriage-mounted gates provide an extra level of safety, as they help contain the material load during vertical travel. This not only safeguards the materials being lifted, it serves as a barrier between workers and materials within the moving carriage.

- Overload Protection – Automatically halts operation to prevent damage to the VRC.

- Emergency Stop Buttons – Strategically located for quick access at all floor levels.

- Limit Switches – Ensures precise stopping at upper and lower positions, avoiding over-travel.

Smart Controls and Diagnostics

Smart controls and remote diagnostics integrate seamlessly into modern, automated environments and include:

- Programmable Logic Controllers (PLC): Enables customizable operational sequences.

- HMI Touchscreen Interfaces: Provide real-time diagnostics and manual override.

- Remote Diagnostics – Enables monitoring of system performance, reducing downtime and maintenance costs.

Material and Environmental Adaptability

No matter the environment, the M Series can be customized with durable materials:

- Stainless Steel Construction: Ideal for wash-down or corrosive areas or food-grade facilities.

- Hot-Dipped Galvanized Finishes: Provides corrosion resistance for outdoor or humid environments.

- Explosion-Proof Components: Suitable for hazardous locations.

Seamless Integration into Automated Systems

The M Series is designed to be seamlessly integrated into warehouse automation systems, allowing businesses to enhance warehouse automation and efficiency with:

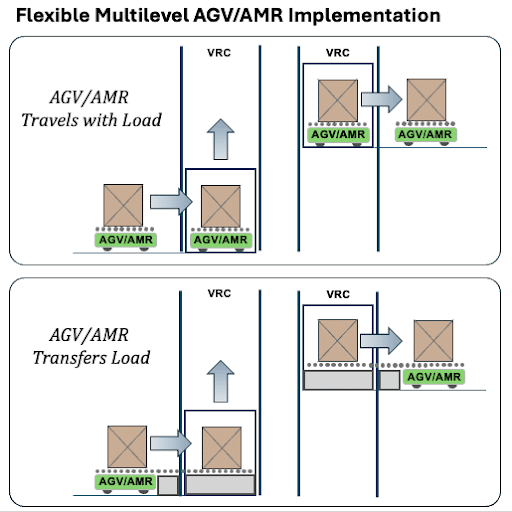

- Integration with AGVs and AMRs – Allows autonomous vehicles to interact directly with the lift.

- Compatibility with Conveyor Systems – Supports seamless material flow between floor levels.

- Advanced Sensors and Signals – Connects to warehouse management systems (WMS) and/or ERP systems for real-time logistics data.

Industry-Specific Vertical Lifting Solutions

With nearly five decades of experience designing custom vertical reciprocating conveyors (VRCs), PFlow Industries engineers its M Series solutions to meet the highest standards of performance, safety, and regulatory compliance across a wide range of industries.

- Warehousing and Distribution Centers – Increase material throughput and maximize floor space with large-capacity carriages, multi-level reach, and automation-ready controls that support high-efficiency logistics operations.

- Manufacturing & Industrial Facilities – Protect workers and equipment with safety enclosures, explosion-proof components, and custom load/unload configurations—all designed to fit seamlessly within your new or existing facility layout and workflows.

- Food Processing Plants – Ensure sanitation and food safety with wash-down safe materials, stainless steel construction, and options tailored for USDA-compliant and hygienic environments.

- E-Commerce & Fulfillment Centers – Support fast-paced order fulfillment by streamlining every stage of your fulfillment workflow, from product arrival and put-away to picking, packing, and SLAM (Scan, Label, Apply, Manifest) operations. M Series VRCs improve order accuracy, reduce cycle times, and enable seamless inventory movement across multiple levels.

Ready to Customize Your M Series VRC?

The M Series is more than just a vertical reciprocating conveyor; it’s a fully customizable material handling solution designed to meet the demands of a wide variety of industries including, modern warehouses, manufacturing plants, and distribution centers. From advanced safety features to smart controls and automated system compatibility, the M Series is built for efficiency, safety, and reliability.

Whether you’re designing a new facility or upgrading an existing operation, PFlow’s M Series Mechanical VRC offers the flexibility needed to solve your specific material lifting challenges.