A vertical reciprocating conveyor (VRC) can transform and improve material handling, productivity, and space utilization in your facility. VRCs take the effort out of moving materials between floors and create a safer working environment.

Designed to move materials and not people, VRCs are capable of things that other lifting means are not. They have the ability to lift loads of almost any weight, shape or size, higher and faster than equipment such as forklifts or scissor lifts. VRCs also have the advantage of an enclosed carriage structure that prevents materials from falling onto workers below as they are raised and lowered.

What problem are you trying to solve?

To ensure you get the maximum benefit from installing a VRC in your facility for years to come, some pre-planning is required, as each VRC is engineered and manufactured to meet your unique material lifting application. Consider the problem(s) for which you are seeking solutions. For example,

- Are you looking for a lower-cost option for freight elevator replacement?

- Do you need to reach floor levels, racking, or pick modules that are not accessible by forklift?

- Do you need a material lifting option that is more flexible and cost-efficient than a freight elevator?

- Do you need a material lifting option that can be used as part of a high-speed / high-cycle automated system?

Read more about how to select the right material lift for your operation.

Answering these questions will help determine the type, capacity, and reach of VRC needed.

For simple, two-level lifting applications that do not require continuous use, a hydraulic VRC may accommodate your needs.

High-speed / high-capacity use applications, applications that require reaching heights of over 22’, and those that require lifting over 6,000 lbs., typically require the use of a mechanical VRC. Mechanical VRCs can lift heavier loads to an unlimited number of floor levels and are capable of continuous cycle use.

Review Workflows

Changes to your existing operation are minimized by selecting a VRC that accommodates your current space. It is important to understand how materials will be loaded and unloaded from the VRC and the space available at each floor level for this activity. Each type of VRC accommodates different loading patterns, (the direction(s) in which the VRC platform is approached for loading and unloading). The three options are:

- C: Load and unload from the same side of the carriage (creating a “C” shape when viewed in profile).

- Z: Load from one side of the carriage and unload from the opposing side (which maintains the same direction of movement).

- 90°: Loads from the front of the carriage and unloads from the side of the carriage.

Choosing the correct loading pattern is critical to ensuring you have the space needed to efficiently load and unload materials.

Select the Optimal VRC Configuration

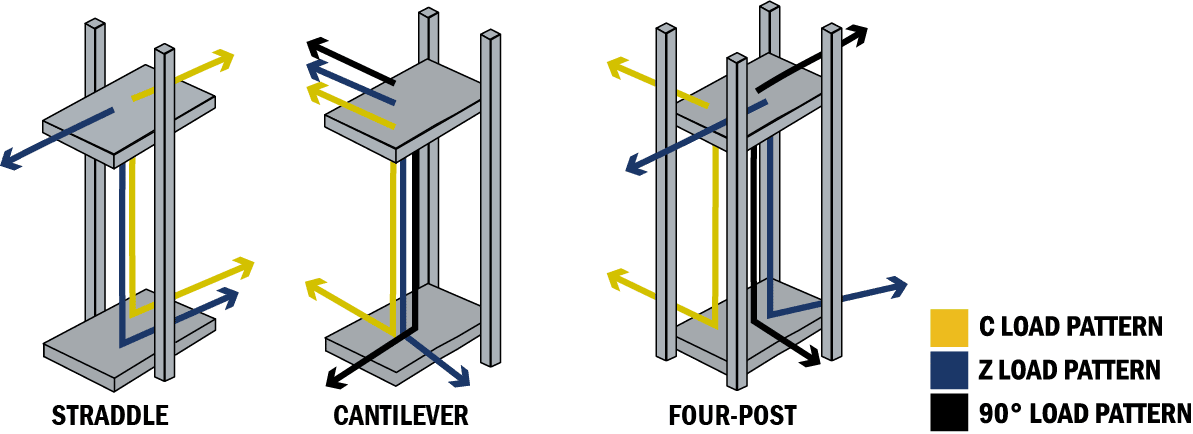

PFlow builds straddle, cantilever, and 4-post VRCs. These terms refer to how the VRC uprights or columns are positioned to support the carriage. Each configuration supports different loading patterns.

In a straddle configuration, the VRC’s carriage is placed between the two guide columns, distributing the weight of the load vertically along the length of both columns. This configuration allows for greater lifting capacity and accommodates C and Z loading patterns and is perfect for applications that do not have space constraints.

In a cantilever configuration, the VRC’s carriage is supported by two guide columns on one side of the carriage. This configuration allows easy access from three sides of the VRC and supports C, Z, and 90° load patterns. Cantilever configurations allow for more loading and unloading flexibility, especially in space constrained areas. This configuration can typically accommodate taller loads than straddle configurations.

The 4-post VRC configuration has the platform mounted within the four guide columns. This allows for maximum lifting capacity and large platform sizes. The 4-post configuration also offers maximum loading flexibility as it accommodates C, Z, and 90° load patterns.

Is a VRC Right for Your Facility?

Integrating a VRC into your existing building can provide access to areas that were once unreachable via other lifting equipment and it allows you to expand up and not out, making the most out of your existing footprint. VRCs can improve material handling safety and increase the overall efficiency of your material handling operations.

There is a lot to consider when making the decision to incorporate a VRC into your existing facility to ensure it meets your needs today as well as your future needs, and PFlow’s VRC experts are here to help you each step of the way.