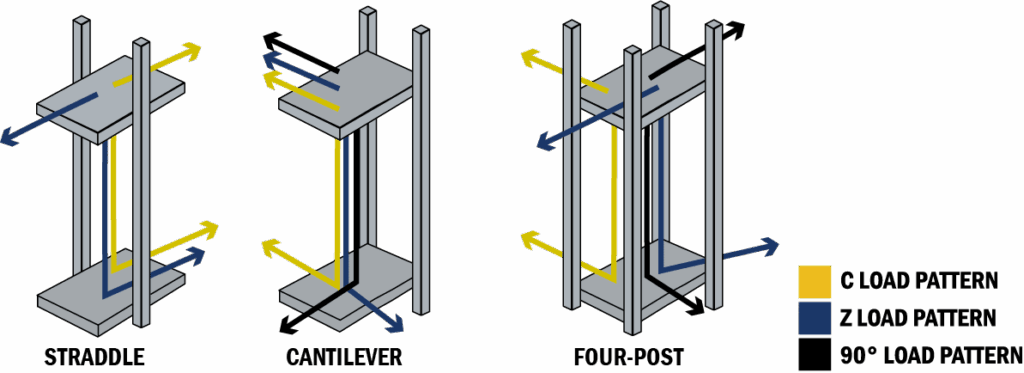

- C Load Pattern: Accommodates loading and unloading from the front of the carriage

- Z Load Pattern: Accommodates loading from one side of the carriage and unloading from the opposite side of the carriage

- 90° Load Pattern: Accommodates loading from the front of the carriage and unloading from the side of the carriage

Straddle, Cantilever or Four-Post: How to Choose the Right Mechanical VRC Design for Your Needs

Straddle Configuration

A straddle configuration supports the carriage (lifting platform) between two guide columns, evenly distributing weight.

Design and Structural Features:

- Carriage (lifting platform) is located between upright guide columns.

- Supports C and Z loading patterns, making it highly versatile.

- Requires more floor space than the cantilever configuration.

Applications:

- Operations that handle heavy, wide, or asymmetrically-loaded materials.

- Moving bulk, oversized, or asymmetrical loads in manufacturing environments.

- Operating in spaces where maximum lifting stability is beneficial.

Advantages:

- Supports greater lifting capacities and larger platform sizes, distributing load forces more evenly.

- Ensures enhanced stability for large platforms and heavy loads.

- Delivers consistent performance in high-volume operations.

Considerations:

- Requires more floor space than a cantilever configured VRC with the same sized carriage. This may not be suitable for facilities that are space constrained.

- Supports C and Z loading patterns, which provide consistent, efficient operation, though it has less flexibility than lifts designed to include 90° loading.

Case Study: PFlow rises to the challenge at a glass plant with a custom M Series two-post Vertical Reciprocating Conveyor (VRC) engineered to lift delicate, desiccant-filled stainless steel spacer channels—over 2-story vertical travel, spanning 17 feet, and handling up to 3,500 lbs on an exceptionally wide carriage (over 26 feet)—ensuring safe, efficient, and precise material flow in the high-volume window assembly process. Heavy Glass Easily Lifted with Extra Wide PFlow Vertical Lift

Cantilever Configuration

A cantilever configuration features guide columns located on one side of the carriage, leaving three sides open for loading and unloading.

Design and Structural Features:

- Ideal for space-constrained areas, as the guide columns are positioned on one side of the carriage, providing unobstructed access on the remaining three sides of the carriage.

- Supports C, Z, and 90° loading patterns, offering maximum flexibility.

- Cantilever design shifts the drive base to one side, freeing up more overhead space for oversized loads.

Applications:

- Warehouses with limited floor space or irregular layouts.

- Operations requiring multi-directional loading/unloading.

Advantages:

- Flexible loading patterns accommodate diverse workflows.

- Maximizes usable loading height when the upper-level ceiling clearance allows full use of extra overhead space.

- Optimized for environments needing quick access from multiple sides.

Considerations:

- Cantilever construction can affect the overall carriage size and load capacity due to asymmetrical force distribution.

- May require additional bracing for heavier loads.

Case Study: PFlow Industries designed a custom two-post cantilever heliport lift for a Shell offshore oil platform, moving up to 1,500 lbs over 32 feet between the helipad and platform deck. Built for harsh marine conditions, it features galvanized steel, stainless hardware, UV-resistant components, and explosion-proof controls for safe, long-lasting performance in hazardous environments.

Four-Post Configuration

The four-post configuration uses structural guide columns at all four corners of the carriage, providing robust support and stability for the heaviest loads.

Design and Structural Features:

- Carriage is supported at all four corners for maximum strength and durability.

- Designed to handle extremely heavy or oversized loads with high platform stability.

- Supports C, Z, and 90° loading patterns, for maximum flexibility.

Applications:

- Lifting of heavy or bulky materials such as automotive components, machinery or equipment, or palletized goods.

- Environments where platform size and load capacity requirements exceed the capabilities of two-post designs.

- Any lifting application that cannot be accommodated by standard lifting equipment.

Advantages:

- Highest load capacity of all VRCs.

- The F Series takes durability to the next level—built tough to handle the heaviest workloads and keep performing year after year.

- Ideal for handling large, heavy, or high-frequency loads.

Considerations:

- Requires the most floor space of the three configurations.

- Offers the most flexibility in load/unload patterns.

Case Study: PFlow engineered a custom four-post mechanical VRC to integrate seamlessly with a 10-story utility tower at a power plant. Designed to lift up to 6,000 lbs across 106 feet of vertical travel, the lift features a 6’ x 6’ platform and operates within a confined shaft space. With challenges including extreme height, limited access, and the need for structural precision, PFlow delivered a high-capacity, code-compliant lift that ensures safe, efficient transport of tools, parts, and equipment across all levels.

PFlow Designs Lift to Integrate with 10-Story Power Plant Tower

Choosing the Right Configuration

When selecting between Cantilever, Straddle, and Four-Post configurations, consider the following factors:

- Load Size and Weight: Four-post configurations are ideal for the heaviest and most demanding loads. Straddle VRCs support heavy, wide, or awkwardly-shaped materials. Cantilever systems are well-suited for lighter, taller, or less centralized loads.

- Space Requirements: Cantilever VRCs are optimized for tight or irregular spaces. Straddle and four-post systems require more floor space, with four-post being the most space-intensive.

- Loading Patterns: Four-Post configurations offer the most flexible load/unload patterns (C, Z, and 90° from all 4 sides of the platform). Cantilever configurations offer the next most flexible loading and unloading (C, Z, and 90°),while Straddle configurations support C and Z patterns.

- Platform Size and Stability: For oversized platforms or maximum stability, both Straddle and Four-Post configurations provide the structural strength needed. Four-post offers the highest capacity and most stable platform support.

- Automation and Integration Needs: With four-sided access on 4-Post lifts and three-sided access on Cantilever models, these VRCs offer the most load/unload pathways for automated operations utilizing AGVs or AMRs.

- Application Environment: If you’re working in high-frequency or industrial environments that demand reliable heavy-duty performance, a Four-Post or Straddle VRC may be the best fit.