The Quantum Drive for Mechanical Lifts

How did this “quantum leap” come about?

Think math. Trigonometry and geometry, specifically. Never fear – we promise this won’t get confusing.

The problem, at its core, is vibration.

As a typical lift travels up or down, its chain pulses. The chain sprocket acts like a polygon (not a circle) as it drives the chain, creating the pulses. Its velocity increases when driving from a peak on the polygon (a tooth), and slows when driving between teeth.

As a typical lift travels up or down, its chain pulses. The chain sprocket acts like a polygon (not a circle) as it drives the chain, creating the pulses. Its velocity increases when driving from a peak on the polygon (a tooth), and slows when driving between teeth.

This pulsing creates vibration. The natural frequency of the lift depends on the chain’s stiffness (which changes as it moves), and the weight hanging on it (which also changes depending on the load being conveyed). When the frequency of the sprocket pulses matches the natural frequency of the lift, the vibration can be magnified to where the carriage bounces, gates and enclosures rattle, and the entire lift shakes. A bit disconcerting, to say the least.

Here’s where math comes in: The pulses occur as a sine/cosine equation. Laws of physics apply. Nothing can be done because, well, these laws are awfully hard to defy.

Unless, of course, you make a simple – but significant – design change.

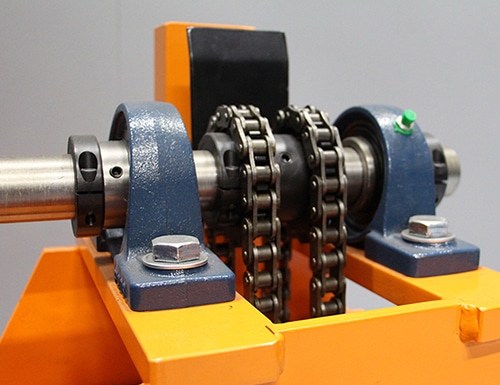

Standard lifts use one chain at each lifting point. The Quantum Drive uses two. The results are immediate and dramatic.

The sprockets on the two chains are arranged so that when one is driving on a tooth, the other is driving between teeth. One pulses as a sine function, the other as a cosine function. Thus the pulses cancel each other out, resulting in smooth, pulse-free operation. The technical term is “chordal suppression.”

Here’s what it means for you: Vibration ends. So does bouncing, rattling, and the general commotion associated with them.

The dual-chain system magnifies safety, too.

All mechanical VRC designs are required by ASME B20.1 to have built-in, carriage-mounted safety cams. PFlow’s safety features are the best in the business. In case of a broken or disconnected lifting chain, the cams engage to prevent the carriage from falling. The abrupt stop, however, can be damaging to surfaces of the guide columns, and to fragile payloads.

On the Quantum Drive, conversely, the safety cams are not deployed unless both chains break – an extremely unlikely scenario. If a single Quantum chain breaks or becomes disconnected, electronic sensors safely stop the lift, without the abrupt and potentially damaging activation of the safety cam.

Each chain can safely support the full-rated load, independent of the other.

The Quantum Drive has another performance-oriented design enhancement: a trapped flange guide system on straddle carriages.

VRCs typically have one large wheel inside the guide column at each of the four guide points. The dimensional tolerances of structural steel beams typically used as guide columns require a significant amount of clearance, between the wheel and the guide surfaces, to ensure free movement of the carriage. If a load is unbalanced, or as loads are moved on and off, the carriage can teeter and rock.

The Quantum Drive erases this effect. Its trapped flange guide system uses eight wheels – four on the inside of the column flange, with four partnered on the outside – to eliminate carriage teetering. Superior stability – and greater safety – results.

The Quantum Drive is now offered as a feature on PFlow’s mechanical two-post lifts. We may add Quantum Drive to other models in the future.

One plus one equals two – which, in the case of the Quantum Drive, equals superior strength, safety and performance. See, the math isn’t too hard after all.