If your vertical reciprocating conveyor (VRC) isn't performing as expected, even a minor issue can disrupt operations and lead to costly downtime. While some problems require expert repair, many can be resolved with a few simple troubleshooting steps.

Below are four easy tips to help you identify and fix common VRC issues before they turn into major disruptions.

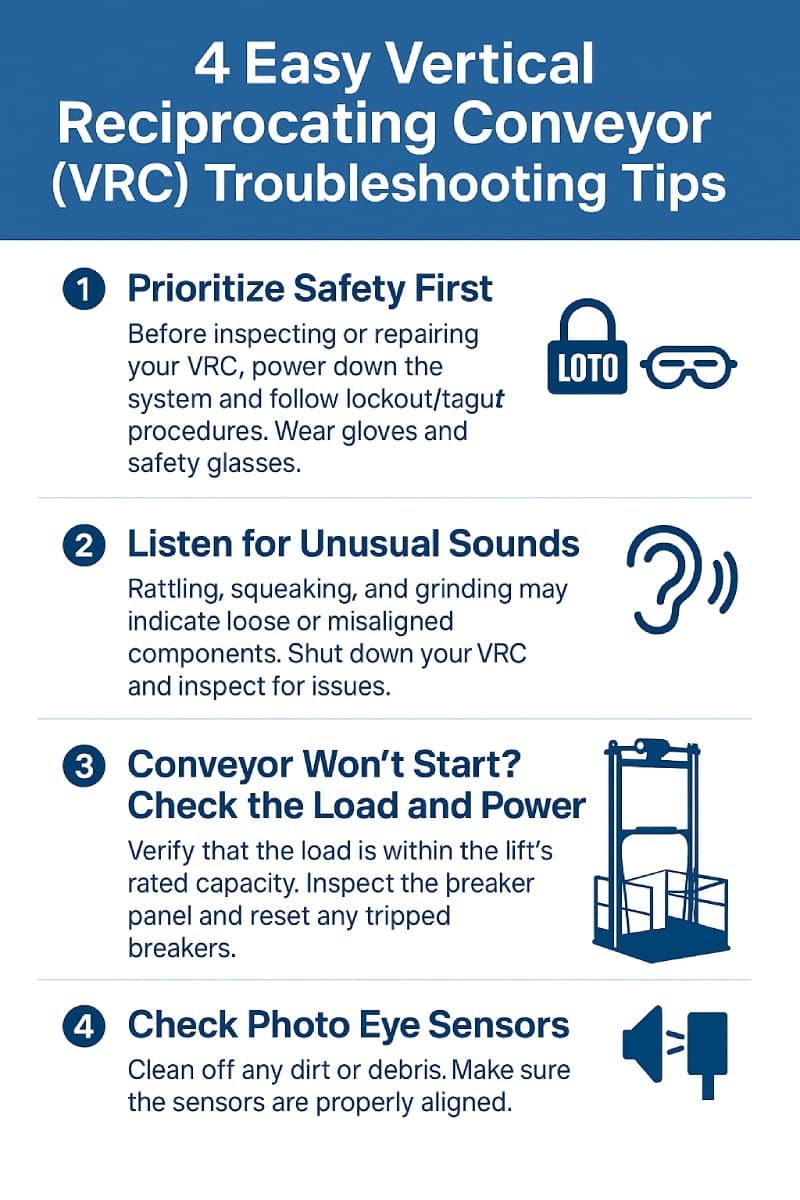

1. Prioritize Safety First

Before inspecting or repairing your VRC, always power down the system and follow proper lockout/tagout (LOTO) procedures. Wear the appropriate personal protective equipment (PPE), including gloves and safety glasses. Never place your hands on moving parts; VRCs use powerful motors and mechanical systems that can cause serious injury if handled carelessly.

Safety should always be your first step in troubleshooting.

2. Listen for Unusual Sounds

A quick way to identify mechanical issues is by simply listening to the machine while it's running. Rattling, squeaking, or grinding noises can indicate problems like a loose drive chain, worn bearings, or misaligned components.

Shut down the equipment and carefully inspect all moving parts. Tighten any loose connections and replace damaged or worn components as needed. Addressing these issues early can prevent long-term damage and costly repairs.

3. Conveyor Won’t Start? Check the Load and Power

If your VRC won’t start at all, don’t panic, it’s likely one of two things: an overloaded lift or a power issue.

Start by verifying that your current load is within the lift’s rated weight capacity. Exceeding this limit can prevent the system from starting or cause the circuit breaker to trip. Next, inspect the breaker panel and reset any tripped breakers. If the breaker continues to trip, there may be an underlying electrical issue, such as a motor overload or short circuit, that requires professional assistance.

4. Check Photo Eye Sensors

One of the most common and easily overlooked VRC issues involves the photo eye sensors. If they’re misaligned or blocked by dust, debris, or packaging materials, the system may stop functioning altogether, even though all other components are working correctly.

Wipe the lenses clean and confirm the sensors are aligned directly with their reflectors. Even a small shift in alignment can disrupt the signal. This quick fix could save you hours of unnecessary troubleshooting.

Need Professional Help?

These troubleshooting tips can help resolve common situations and keep your VRC running smoothly. For complex concerns or major malfunctions, protect your investment by relying on the team that pioneered the vertical reciprocating conveyor.

Contact the experts at PFlow for service, technical support, or to schedule a system inspection. We’re here to help you keep things moving.