If you own a factory or warehouse, you need to use a number of different implements in order to move items and inventory.

There are a number of benefits offered by vertical conveyors that you won’t find in other such implements. They are as follows:

Benefits of a VRC

1. Safety

Perhaps the greatest benefit of vertical conveyors is that they’re extremely safe to operate. This is in direct contrast to similar implements such as forklifts, which have a history shrouded in danger.

Vertical lifts can be made with all different types of materials to ensure that they avoid harmful disaster. They can hold various amounts of weight, meaning that you can have one custom made to safely hold the items that you deal with.

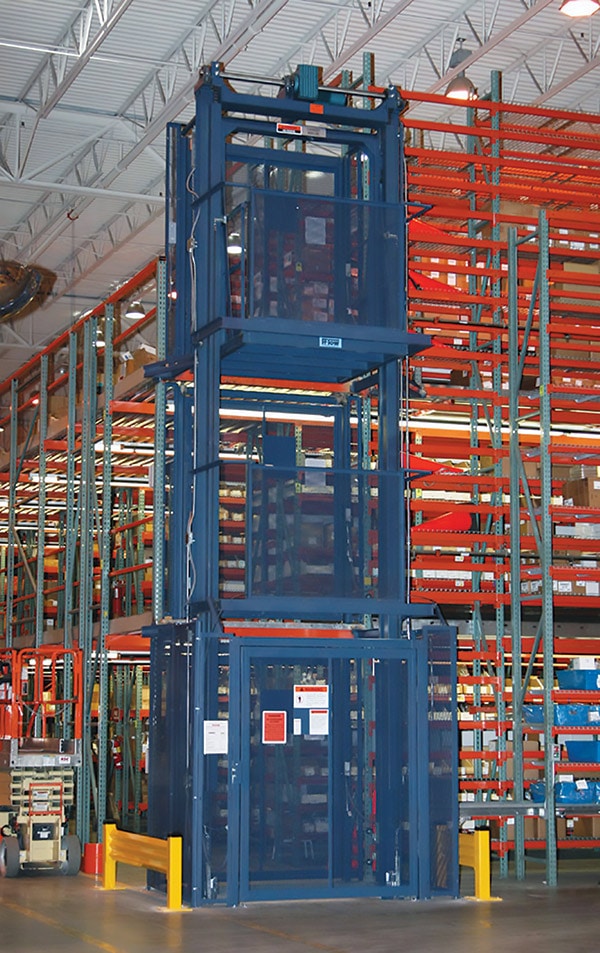

VRCs come in many different types, and can also be custom made. They have varying weight capacities, parts, speeds, and more to ensure that each lift can correctly and safely perform its function. If you would like to learn more about the safety features, click here.

2. Relative Affordability

While they can initially be a little more expensive than forklifts, vertical lifts will pay themselves off hundreds of times over as time passes by because they have much lower costs of operation and maintenance,

Compared to freight elevators, the costs are significantly lower. This is because they don’t have to be built to hold humans, which allows VRCs undergo a much less costly standardization process.

3. Maximized Efficiency

Having a material handling vertical lift in place at your warehouse will ensure a consistent workflow at all times. A forklift can not match this efficiency because they are operated by humans and people are inherently prone to error.

Vertical lifts go up when they’re told to go up, and they go down when they’re told to go down. Having a responsive lift such as this on your conveyor line will only contribute to increased efficiency.

4. Easy to Install

Vertical reciprocal conveyors can be installed just about anywhere. Not only can they be set up against the side of a wall, but they can also be set up inside of existing elevator shafts or outside.

When compared to freight elevators, vertical lifts are much easier to install. Because they’re so simple to install, they’re also relatively inexpensive.

5. Designed to Fit Your Exact Needs

Maybe the greatest benefit of VRCs is that they can be custom designed to meet your exact standards. Moving flammable items? Your conveyor can be made out of materials which prevent flame hazard. Need to save as much space as possible? Your conveyor can be designed in a compact and narrow fashion. Looking to move items which weigh more than 10,000 pounds? A conveyor can be specifically designed to accommodate your maximum weights.