Weld-Free VRC Solutions

PFlow’s Adjustable Bolted Bracing allows for safe and efficient VRC installations in facilities where welding is restricted or outright prohibited.

With 3-way adjustability and a seismic-rated, engineering-certified design, our weld-free solution makes VRC installation possible in cleanrooms, flammable environments, and other sensitive applications, without compromising safety or stability.

Benefits of Weld-Free VRC Solutions

No Welding Required

Eliminates the fire, safety, and permitting risks associated with traditional welded installations—ideal for cleanrooms, flammable environments, and confined spaces.

Lower Installation Costs

Avoids the high labor rates of certified welders, reduces permitting and compliance expenses, and shortens install time, leading to significant project cost savings.

Seismic-Rated Design

Backed by a professional engineering stamp and designed to withstand seismic forces, PFlow’s adjustable bolted bracing meets the highest safety and compliance standards.

How Adjustable Bolted Bracing Works

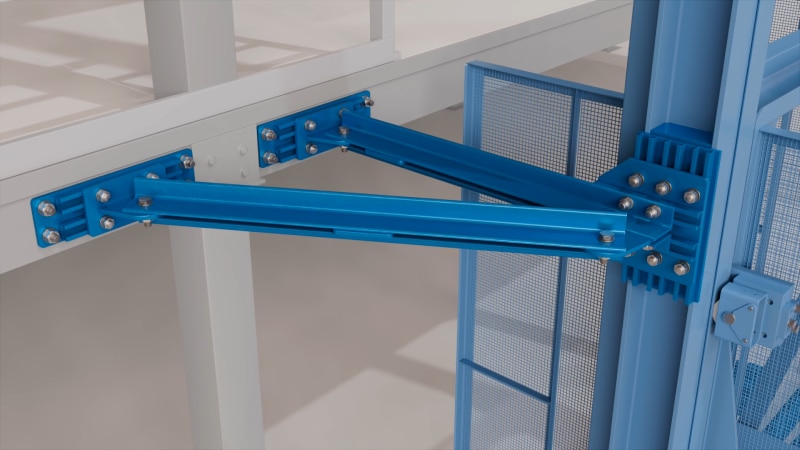

PFlow’s Adjustable Bolted Bracing system is an innovative alternative to traditional welded bracing, designed specifically for VRC applications at the edge of a mezzanine. This solution is ideal for facilities that prohibit hot work due to safety, contamination, or regulatory concerns. Rather than welding supports directly to the structure, installers use a bolt-and-strut configuration that provides structural integrity without introducing the risks of fire, fumes, or production disruption due to hot work.

The system includes two adjustable bracing struts mounted to the VRC columns at the factory. These allow for both vertical and horizontal adjustments during installation. A third adjustable strut connects to the mezzanine, offering horizontal adjustability to securely anchor the lift. This three-point adjustability simplifies alignment, speeds up installation, and allows fine-tuning in the field, making it especially useful for retrofit applications or facilities with strict compliance requirements.

Why PFlow?

PFlow holds numerous VRC lift patents thanks to our heavy investment in research and development. We’ve worked closely with lawmakers to develop the existing state codes to ensure increased safety.

We boast the biggest engineering team in the industry and incorporate their safety innovations, breakthroughs, and new features into our lifts.

“PFlow makes great equipment; I have been doing this for 30 years, installing material lifts, elevators and dumb waiters, and in my opinion PFlow is the top quality of equipment out there.”

– Kevin Mannes, Managing Partner, Florida Lifts

Frequently Asked Questions

This solution is ideal for installation in environments such as:

- Semiconductor

- Food and beverage manufacturing

- Pharmaceutical

- Biotech

- Aerospace

- Defense

- Warehouse & Distribution

- Oil, gas, energy, utilities

- Hospitals and healthcare

- Any site where welding or hot work is prohibited or heavily restricted

Contact PFlow to see if Adjustable Bolted Bracing is a fit for your facility.

This solution is ideal for installation in the following environments:

- Semiconductor or cleanroom

- Food and beverage manufacturing

- Pharmaceutical

- Biotech

- Aerospace

- Defense

- Warehouse & Distribution

- Oil, gas, energy, utilities

- Hospitals and healthcare

- Facilities with flammable materials, confined spaces

- Any site where welding or hot work is prohibited or heavily restricted

Yes. PFlow’s system is seismic rated and backed by a professional engineering stamp, certifying it meets strict structural and safety standards without requiring welding.

The bolt-on bracing eliminates the need for certified welders, permits, and fire watch personnel. Its three-way adjustability allows installers to make quick, precise adjustments on-site without cutting or rework.

No additional maintenance is required beyond standard VRC inspection routines. The bolted system is durable, reliable, and built for long-term performance.